In recent years, 3D printing has evolved from a prototyping tool to a transformative force in manufacturing. Industries ranging from aerospace to automotive are embracing additive manufacturing not just to save time and cost, but to innovate in ways that were previously unimaginable. At the heart of this revolution lies one critical factor — materials. And more specifically, high-performance filaments. These advanced materials are changing the game by pushing the limits of what 3D-printed parts can do, especially in demanding manufacturing environments.

What Are High-Performance Filaments?

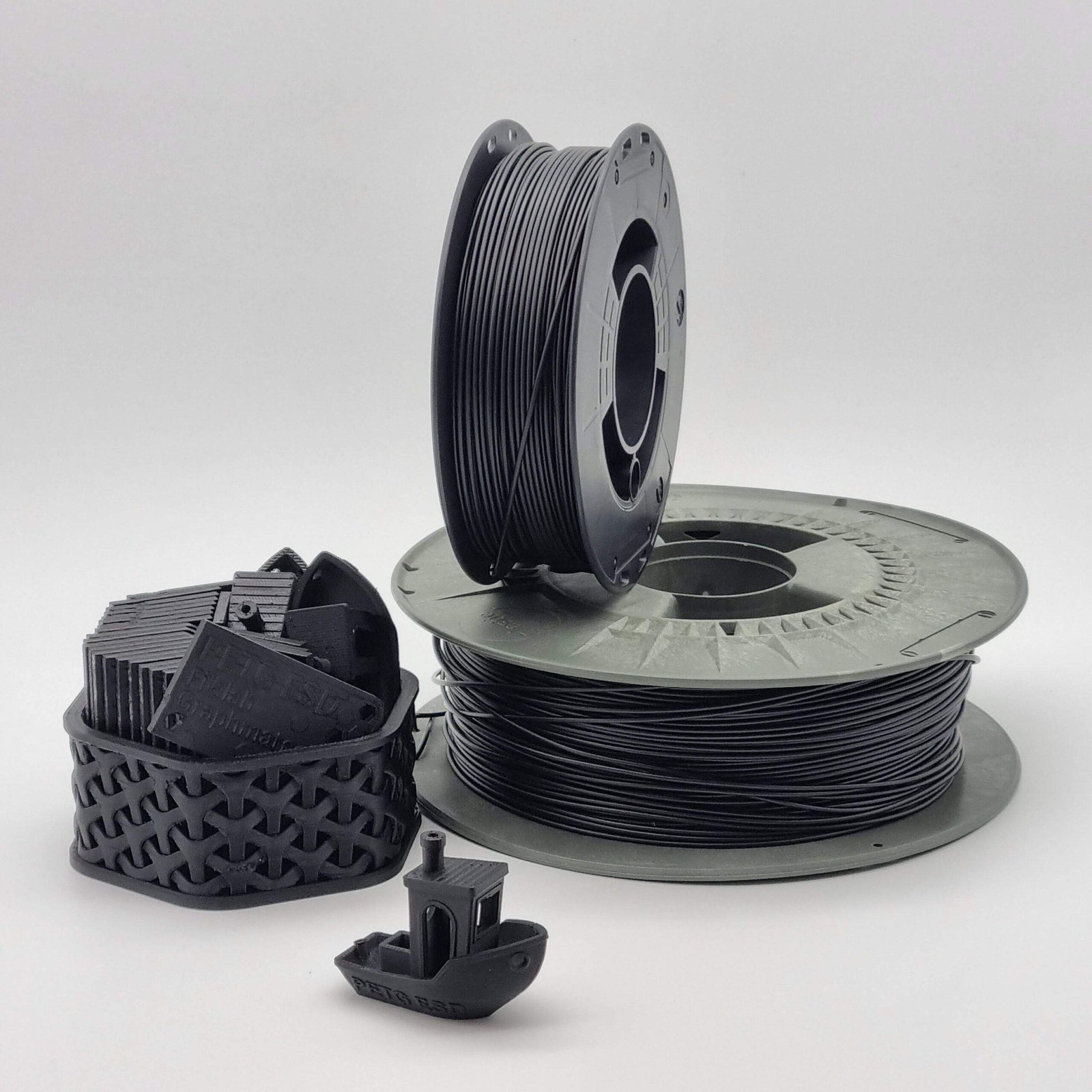

High-performance filaments are a class of 3D printing materials engineered to offer exceptional strength, thermal resistance, and chemical durability. Unlike standard filaments like PLA or ABS, these materials can withstand extreme conditions while maintaining dimensional stability. They are ideal for producing functional end-use parts and prototypes that need to perform under stress.

Some of the most popular high-performance filaments include:

- PEEK (Polyether ether ketone): Known for its incredible mechanical strength and heat resistance, PEEK is widely used in aerospace and medical applications.

- ULTEM (PEI – Polyetherimide): Offers flame retardancy, excellent thermal properties, and is often found in aircraft interiors and electronics.

- Nylon: Offers flexibility and durability, often reinforced with carbon fiber for added strength.

- Carbon Fiber-Reinforced Filaments: These are composites where carbon fiber is blended with base materials like Nylon or PETG to improve rigidity and performance.

Key Advantages in Manufacturing

Using high-performance filaments in industrial 3D printing provides a host of advantages, making them ideal for replacing metal parts or enhancing product development.

- Mechanical Strength & Heat Resistance

High-performance filaments can endure high loads and temperatures. For example, ULTEM and PEEK can withstand continuous use in environments exceeding 200°C, making them suitable for aerospace engine components or under-the-hood automotive parts. - Chemical & Environmental Resistance

These filaments resist degradation from solvents, fuels, and chemicals — critical for producing parts used in harsh environments like oil rigs, chemical plants, and medical sterilization equipment. - Design Flexibility

Complex geometries and lightweight designs are more easily achievable with high-performance materials, allowing engineers to reimagine traditional manufacturing limitations. - Lower Tooling Costs

By replacing metal parts in certain applications, manufacturers save on the cost and time of custom tooling, especially in low to medium volume production.

Industry Applications Using High-Performance Filaments

These advanced materials are being adopted across various sectors:

- Aerospace: Lightweight yet strong components such as brackets, ducts, and housings are printed using ULTEM or carbon fiber-reinforced materials.

- Automotive: From jigs and fixtures to under-hood parts, these filaments are helping reduce vehicle weight and increase fuel efficiency.

- Medical & Dental: Sterilizable, biocompatible filaments like PEEK are used for surgical instruments, implants, and custom dental devices.

- Electronics: Parts requiring flame retardancy and high precision, such as housings or connectors, benefit from ULTEM and other advanced polymers.

Challenges and Considerations

Despite their advantages, high-performance filaments are not plug-and-play. They require specific hardware and conditions to deliver optimal results.

- Printer Capabilities: These filaments need higher extrusion temperatures (often above 300°C), heated print beds, and in many cases, enclosed or heated chambers.

- Material Cost: High-performance materials are more expensive than standard filaments, though their value becomes evident in critical-use applications.

- Post-Processing: Parts printed with advanced filaments may require more extensive post-processing and careful handling due to the material properties.

Choosing the right filament involves balancing performance needs with printability and total cost.

Future Trends in 3D Printing for Manufacturing

The integration of 3D printing into smart manufacturing ecosystems is accelerating. As part of Industry 4.0, high-performance filaments are enabling digital workflows that combine automation, real-time monitoring, and cloud-based control. Additionally, we’re seeing the development of next-gen composite materials that blend flexibility, strength, and thermal resistance even further.

As high-temperature-capable desktop 3D printers become more accessible, smaller manufacturers and startups are gaining the ability to produce industrial-grade parts without needing expensive injection molding tools or CNC equipment.

Why Choose FilaLab for High-Performance Filaments

At FilaLab, we’re committed to equipping innovators with the materials they need to build the future. Our range of high-performance filaments includes premium PEEK, PEI, carbon fiber-reinforced Nylon, and more — all manufactured to meet rigorous quality standards. Whether you’re prototyping a functional assembly or producing end-use parts, our filaments are tested for consistent diameter, low moisture absorption, and high thermal stability.

We don’t just sell filament — we help manufacturers, designers, and engineers succeed with expert advice and responsive support. Our team is here to guide you through your material selection process and ensure your results exceed expectations.

Conclusion

High-performance filaments are unlocking new possibilities in industrial manufacturing — enabling lighter, stronger, and more efficient parts to be produced directly from a 3D printer. As industries continue to move toward agile, on-demand production models, these materials are set to play a central role. Whether you’re pushing boundaries in aerospace or building robust medical devices, the right filament can be the foundation of your success.

Explore the power of high-performance materials with FilaLab — where advanced manufacturing begins.