3D printing has come a long way from prototyping to becoming a legitimate solution for producing end-use functional parts. Whether you’re printing components for the automotive industry, creating custom fixtures, or developing tools that need to withstand real-world conditions, choosing the right filament can make or break your part’s success. The ideal filament isn’t just about compatibility with your printer — it’s about matching the material properties to the mechanical, thermal, and chemical demands of your application.

Let’s break down what matters when selecting the best filament for functional, final-use components — and how FilaLab.shop can help ensure quality and reliability.

What Are End-Use Functional Parts?

End-use parts are 3D printed components that are used directly in the final product or for real-world tasks, not just as prototypes. These parts must often endure physical loads, repetitive motion, heat, or chemical exposure. They’re expected to last and perform just like traditionally manufactured parts, which means material selection is critical.

Applications include:

- Automotive brackets, clips, housings

- Drone or robotics components

- Medical or lab device holders

- Fixtures, jigs, and production tools

- Consumer electronics enclosures

Key Properties to Evaluate in Filaments

When printing end-use parts, the basic PLA won’t always cut it. You need materials with more advanced performance characteristics. Here are some of the core features to assess:

- Mechanical Strength: Consider tensile strength, flexibility, and impact resistance. Nylon and polycarbonate shine in this area.

- Heat Resistance: Look at the glass transition temperature (Tg) and heat deflection temperature (HDT). Polycarbonate and PEEK are top-tier in high-heat environments.

- Chemical Resistance: Filaments like PETG or Nylon hold up better in oily, humid, or solvent-exposed conditions.

- Dimensional Accuracy: Warping or shrinkage can affect fit and tolerances. Consider reinforced filaments for improved stability.

- Aesthetics (Optional): For parts that need to look good as well as perform, surface finish might matter — especially in consumer-facing applications.

Filament Types Ideal for End-Use Parts

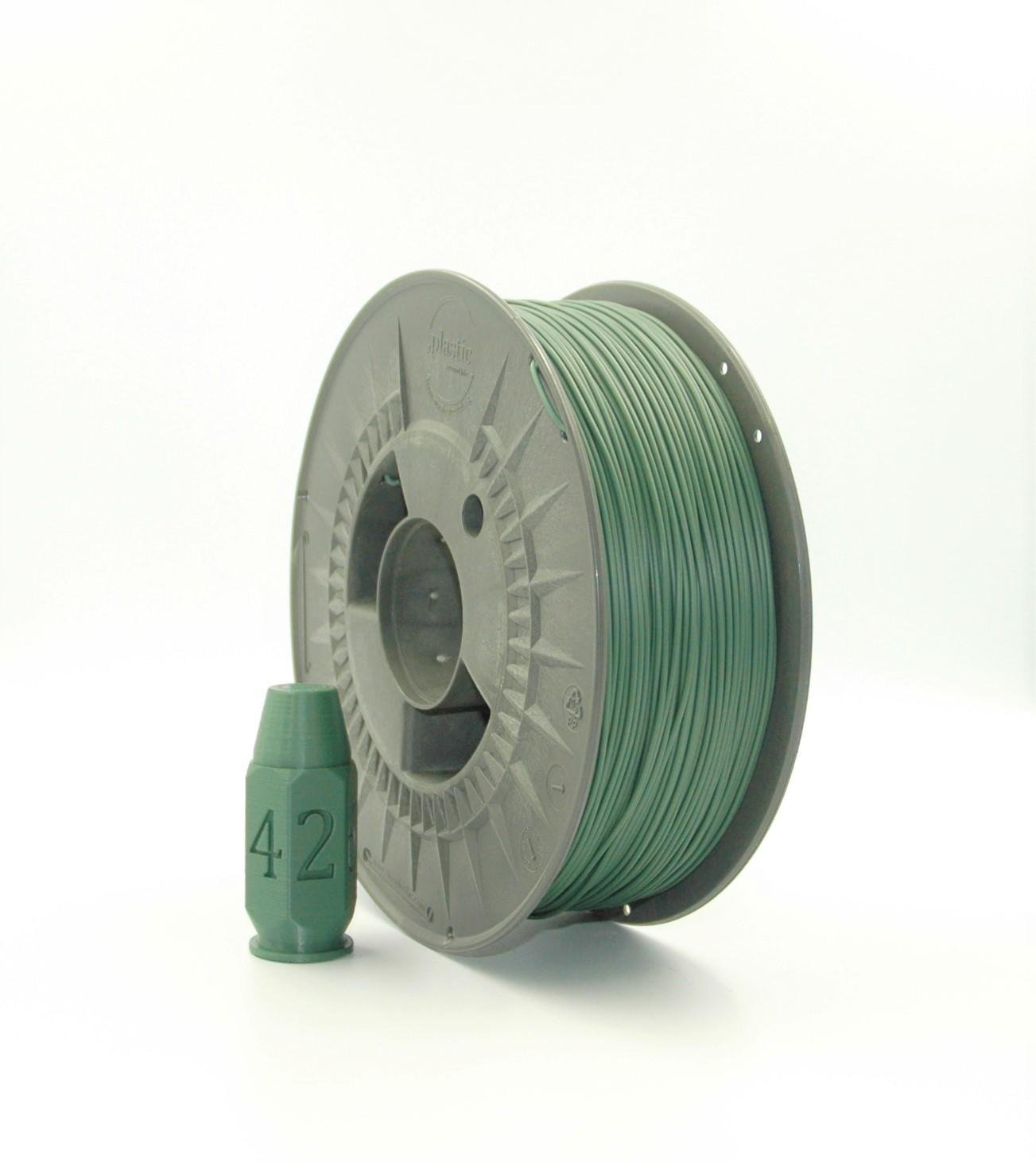

Let’s go over some of the most popular high-performance filaments available at FilaLab.shop that meet the demands of functional parts:

- Nylon (PA12, PA6): Known for strength, flexibility, and abrasion resistance. Excellent for moving parts, gears, or hinges.

- Polycarbonate (PC): Offers high impact resistance and excellent heat tolerance. Great for enclosures or protective gear.

- PEEK / PEKK: Advanced, industrial-grade thermoplastics that are highly resistant to temperature, chemicals, and mechanical wear. Ideal for aerospace, medical, and high-stress components.

- PETG: Easy to print, good mechanical strength, and chemically resistant. A middle ground between PLA and ABS.

- ABS: A solid choice for users needing strength and temperature resistance, with good post-processing potential.

- Carbon Fiber-Reinforced Filaments: These materials offer added rigidity and reduced weight. Ideal for parts that need dimensional stability and minimal flex.

Matching Filament to Application

It’s not just about picking the strongest material. The context of use is essential.

- For Load-Bearing Parts: Go for Nylon or carbon fiber blends to balance strength and flexibility.

- For High-Temperature Use: Polycarbonate, PEEK, or PEKK can tolerate extreme heat without deforming.

- For Chemical Exposure: PETG or Nylon hold up well in oily, wet, or chemically aggressive environments.

- For Food-Safe or Medical Use: Look for certified filaments like food-grade PETG or medical-grade PEEK, depending on the application.

Printability vs. Performance: Striking the Right Balance

Higher-performance materials often require more advanced hardware:

- Heated bed and enclosed chamber (especially for ABS, PC, and Nylon)

- Hardened nozzles for abrasive materials like carbon fiber

- Precision extrusion for minimizing warping

Sometimes, you may need to balance ease of printing with functionality. For example, PETG is easier to print than Nylon, but Nylon offers better wear resistance. Your choice should depend on whether long-term durability outweighs print convenience.

Test and Validate Your Choice

Before moving to production, always:

- Print small test samples

- Validate the mechanical properties under stress

- Adjust infill patterns, wall thickness, and orientation to optimize part strength

A weak print can often be salvaged through proper design — not just material selection.

Trusting the Right Supplier: Why FilaLab.shop Matters

Choosing the right filament is one thing. Choosing the right supplier is another. At FilaLab.shop, we focus on quality, consistency, and expert support to help you get the most out of every spool.

We offer:

- A curated selection of high-performance and engineering-grade filaments

- Detailed technical specs so you can choose with confidence

- Reliable stock and fast shipping to keep your production on track

For professionals, creators, and engineers building real, lasting solutions — FilaLab.shop is your go-to materials partner.

Final Thoughts

When it comes to printing parts meant to function in the real world, material matters. Each filament brings a unique set of strengths and limitations. By understanding the demands of your specific application — and sourcing your materials from a trusted supplier like FilaLab.shop — you can confidently produce 3D printed components that don’t just look good, but perform at a professional level.

Explore our collection today and get expert-backed filament that helps your ideas go further.