When it comes to 3D printing for the outdoors, few materials strike the right balance between durability, flexibility, and weather resistance like PETG. Whether you’re printing a flower pot hanger, a protective outdoor casing, or signage that needs to survive the elements, PETG (Polyethylene Terephthalate Glycol) might just be your go-to filament. But before you start that next outdoor project, there are some key things you need to know about how PETG performs outside. Let’s dive into what makes PETG a reliable choice for the outdoors — and where its limits lie.

What Is PETG?

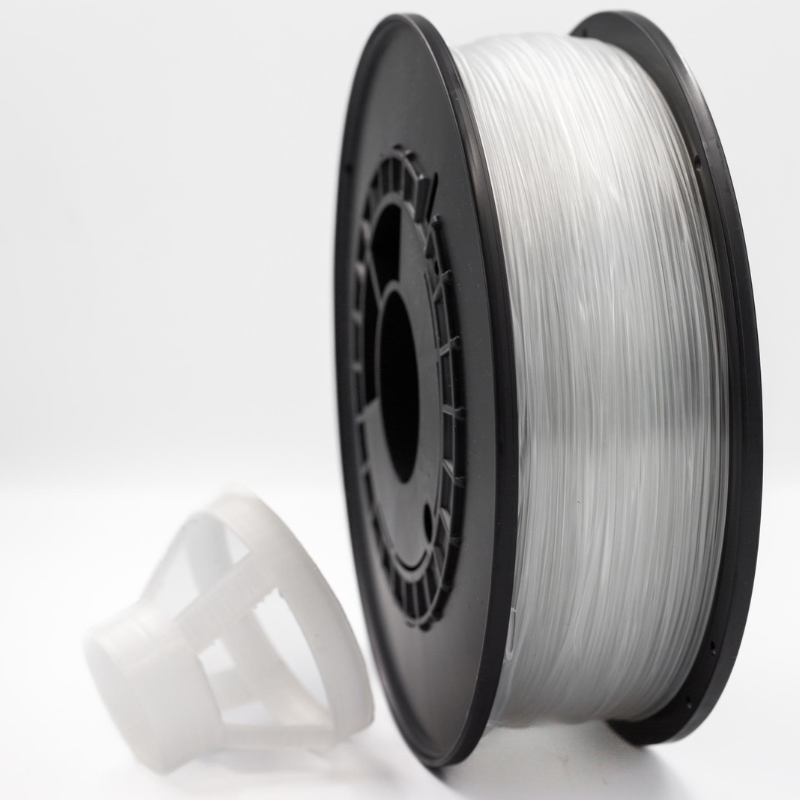

PETG is a glycol-modified version of PET, the same plastic used in water bottles and food packaging. The added glycol improves its clarity and impact resistance, making PETG a tough, slightly flexible filament that combines the ease-of-use of PLA with the strength and heat resistance of ABS — without the headaches of warping. What truly sets PETG apart is its chemical resistance and its ability to maintain structural integrity in demanding environments, making it ideal for functional, real-world applications.

Why PETG Is Suitable for Outdoor Use

The biggest advantage of PETG for outdoor projects lies in its resilience to UV rays, moisture, and temperature variations — three elements that quickly degrade many other 3D printing materials. UV Resistance: While PETG isn’t as UV-resistant as ASA, it outperforms PLA and ABS. It won’t rapidly degrade in sunlight, and minor discoloration is the worst you might expect after prolonged exposure. Moisture Resistance: PETG is hydrophobic, meaning it resists water absorption. It won’t swell or become brittle from humidity or rain, which is crucial for outdoor pieces like plant hangers or tool holders. Temperature Tolerance: With a higher glass transition temperature (~80°C) than PLA, PETG won’t melt or warp easily under summer heat. It’s also more stable in colder temperatures, maintaining its flexibility where PLA might crack. Impact Strength: PETG’s impact resistance is another bonus — it can withstand physical stress like accidental knocks or pressure from wind without snapping.

Limitations of PETG in Outdoor Environments

While PETG holds up well outdoors, it’s not invincible. Here’s what to watch out for: Color Fading: Extended sun exposure may eventually cause fading, especially in lighter or transparent PETG filaments. Surface Wear: PETG’s glossy surface can dull or scratch over time when exposed to dust, debris, or physical wear. Heat Distortion: Though more heat-tolerant than PLA, PETG can still soften in extreme temperatures (above 80°C), making it less suitable for parts that will sit in direct sunlight in hot climates unless supported properly. For extremely demanding outdoor uses, materials like ASA or polycarbonate blends might be better suited. But for the average DIY outdoor project, PETG offers the best mix of performance and printability.

Best Outdoor Applications for PETG

Not sure where to use PETG outdoors? Here are a few great ideas: Garden Accessories: Hose holders, tool organizers, or custom plant labels. Outdoor Signage: Sturdy and clear prints for address plaques or direction signs. Protective Enclosures: Weather-resistant boxes for electronics or irrigation systems. Bike & Car Accessories: Phone mounts, cable holders, or clips that face outdoor stress.

Tips for Printing PETG for Outdoor Projects

To get the most out of your PETG prints, especially for outdoor use, follow these best practices: Nozzle Temperature: Typically between 230°C and 250°C. Lower temps can cause under-extrusion, while too high might lead to stringing. Bed Temperature: 70–90°C is ideal. PETG sticks well, so use a glue stick or PEI surface to prevent excessive adhesion. Cooling: Minimal cooling is best. Too much fan can reduce layer adhesion and compromise part strength. Print Speed: Slower is better — around 30-50mm/s ensures strong inter-layer bonding. Post-Processing: Use a UV-resistant spray or coating to boost long-term performance outdoors and maintain color vibrancy. Also, not all PETG is made equal. Choose high-quality PETG filament like those available on FilaLab.shop, which are tested for consistency, strength, and color retention.

Maintenance and Longevity of PETG Outdoors

If you’re keeping your PETG prints outdoors all year long, a bit of maintenance goes a long way: Cleaning: Wipe off dirt and debris occasionally with a damp cloth. Storage in Off-Seasons: If prints are only used seasonally (e.g., garden tools), consider storing them indoors during winter. Reprint Timeline: Depending on UV exposure and usage, PETG prints may last several years, but check periodically for signs of wear or brittleness.

Final Verdict: Is PETG Right for Your Outdoor Project?

PETG strikes a great balance between performance, durability, and ease of printing. While it may not have the extreme UV protection of ASA or the sheer toughness of nylon, it delivers reliable, weather-resistant results that outperform PLA and ABS in most outdoor scenarios. For DIY projects, functional outdoor parts, or decorative pieces exposed to the elements, PETG is an excellent choice — especially if printed and finished properly. So, if you’re ready to tackle your next outdoor 3D printing challenge, explore the high-performance PETG filament options available at FilaLab.shop — and bring your projects to life with confidence.