If you’re looking to achieve real, authentic wood texture in your 3D prints, wood PLA filaments are your best friend. For a deep dive into getting the perfect wood finish, check out this comprehensive guide on creating real wood texture with PLA fiber. But as many makers have discovered, scaling up your prints with wood PLA brings its own set of challenges—most notoriously, the dreaded nozzle clog. Large-scale prints mean longer hours, higher material flow, and more chances for something to go wrong. The good news? With a bit of planning and know-how, you can enjoy beautiful, clog-free prints, even on the biggest projects.

Understanding Wood PLA: What Makes It Unique

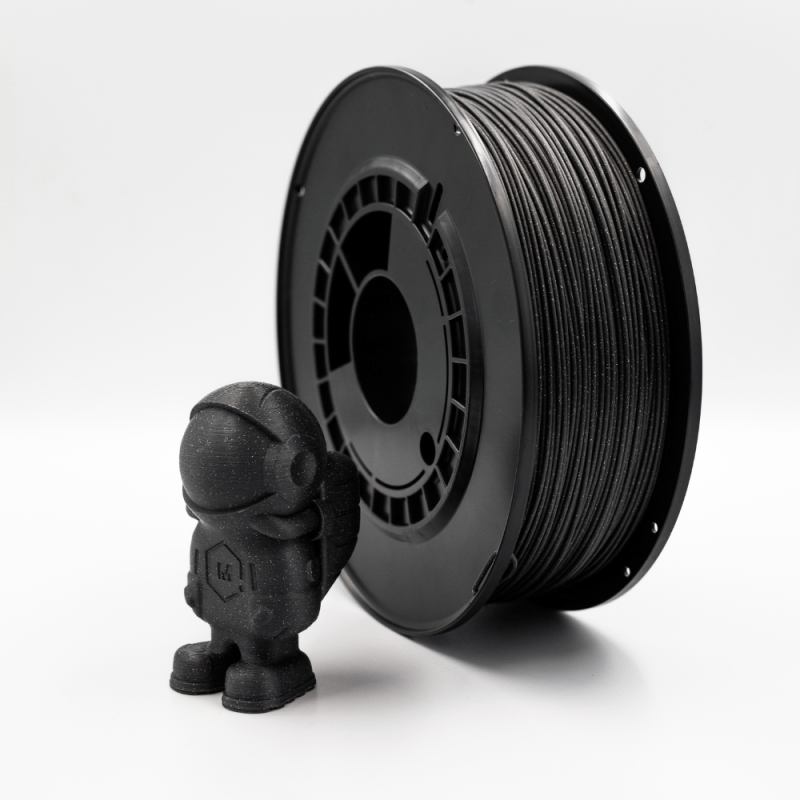

Wood PLA is a composite material made from standard PLA blended with finely ground wood particles. This gives your prints a warm, natural look and even a subtle wood scent. However, those same organic particles can make printing, especially at large scales, tricky. As you print larger objects, your printer must push more material through the nozzle for extended periods, increasing the likelihood that wood particles will get stuck, charred, or otherwise clog up your hotend.

The Real Cause of Clogs in Large-Scale Wood PLA Printing

Nozzle clogs with wood PLA typically happen for three main reasons:

- Particle Buildup: Wood particles aren’t as uniform or meltable as pure PLA. Over time, especially during long prints, these can accumulate in the nozzle, leading to partial or full blockages.

- Thermal Degradation: If your hotend runs a bit too hot or the print pauses (even for a few minutes), wood particles can scorch, creating burnt debris that jams your nozzle.

- Inadequate Nozzle Size: Many users try to print wood PLA with a standard 0.4mm nozzle. This works for small objects but isn’t reliable for large, multi-hour jobs where more flow and more particles increase clog risk.

Choosing the Right Printer and Nozzle Setup

Your hardware setup can make or break your experience with large-scale wood PLA prints.

- Nozzle Diameter: Upgrade to at least a 0.5mm or 0.6mm brass or hardened steel nozzle. This allows larger wood particles to pass through more easily and reduces the likelihood of blockages.

- All-Metal Hotend: Wood PLA is mildly abrasive, and frequent large prints will wear out standard PTFE-lined hotends. An all-metal hotend stands up better to both heat and abrasion.

- Temperature and Speed: Start with the lower end of the filament’s recommended temperature range (typically 200–220°C) and adjust up if you notice under-extrusion. Printing a little slower (40–60mm/s) ensures even melting and prevents jams.

Pre-Print Preparation: The Foundation for Success

Proper prep work prevents a world of headaches during long prints.

- Dry Your Filament: Wood PLA absorbs moisture from the air, which can cause bubbles and clogs. Store your filament in a dry box and, if possible, dry it in a filament dryer for a few hours before big prints.

- Check and Clean Your Nozzle: Before every large job, heat the nozzle and run a cleaning filament through it to clear any lingering debris.

- Slicing Settings: For large prints, increase the layer height to 0.2–0.3mm and keep retraction minimal to reduce the risk of clogging during travel moves.

In-Print Monitoring and Troubleshooting

Even with great prep, always keep an eye on your printer during the first few layers of a big job. Watch for:

- Signs of Under-Extrusion: Gaps, skipping, or “spitting” noises from the hotend often mean a partial clog.

- Color Changes or Smoke: If you see the filament darken or spot wisps of smoke, your temperature may be too high and burning the wood particles—lower it slightly.

- Layer Shifts or Nozzle Drag: These can indicate the nozzle is beginning to block, causing backpressure.

If you notice any of these, pause the print, clean the nozzle, and adjust your settings before continuing.

Post-Print Maintenance for a Long-Lasting Setup

Once your print is done, invest a little time in cleanup:

- Cold Pulls: Use a cleaning filament or nylon to perform a cold pull and remove stuck particles from the nozzle.

- Routine Checks: Inspect your nozzle for buildup or wear and replace it regularly, especially if you’re running many large wood PLA jobs.

- Proper Storage: Always store wood PLA in a dry, airtight container with silica gel packets to prevent moisture uptake.

Pro Tips for Clog-Free, Beautiful Large-Scale Prints

- Use Draft Shields: Adding a draft shield or skirt in your slicer can help prime the nozzle and catch early signs of extrusion issues.

- Experiment with Layer Height: Larger layer heights are more forgiving for wood PLA and can make your print both faster and more reliable.

- Swap Nozzles as Needed: Don’t hesitate to switch to a fresh or larger nozzle if you plan on a particularly big project.

Conclusion

Printing large-scale models with wood PLA isn’t just possible—it can be reliably stunning with the right strategy. By choosing the right nozzle, preparing your materials, and staying alert during prints, you’ll avoid most clogging nightmares and unlock new creative potential. Embrace the learning process, and don’t forget to explore more advanced techniques in the full guide to real wood textures to truly master wood PLA printing at any scale.