Introduction

The world of 3D printing is as much about creativity as it is about choosing the right materials. With a growing array of options available, the decision of which filament to use can make or break your project. Among the most popular choices are PLA Filament and PETG Filament, each offering unique benefits, characteristics, and use cases. The big question facing makers today is: PETG vs PLA filament, which is better for your 3D prints? In this comprehensive guide, we’ll break down the differences, compare their strengths and weaknesses, and help you select the filament that best suits your needs.

What Are PLA and PETG?

PLA: The Basics

PLA Filament, short for Polylactic Acid, is a biodegradable thermoplastic derived from renewable resources like corn starch or sugarcane. It’s renowned for being user-friendly, making it a top choice for both beginners and experienced 3D printing enthusiasts. PLA Filament melts at relatively low temperatures, emits little odor, and produces minimal warping, making it ideal for creating detailed, visually appealing objects.

Common uses:

- Prototypes and concept models

- Educational tools

- Toys and figurines

- Decorative items

Pros: Easy to print, environmentally friendly, excellent surface finish

Cons: Lower heat and impact resistance, less flexible

PETG: The Basics

PETG Filament, or Polyethylene Terephthalate Glycol, is a durable and versatile material favored for its strength and flexibility. It’s a modification of PET (used in water bottles) with added glycol, making it less brittle and easier to work with. PETG Filament is known for its chemical resistance, higher impact strength, and impressive layer adhesion.

Common uses:

- Functional prototypes

- Mechanical parts

- Food containers (where safe)

- Outdoor and utility items

Pros: High durability, chemical and moisture resistance, greater flexibility

Cons: Can string or ooze, may require fine-tuning

Head-to-Head Comparison: PLA vs PETG

Printability

When comparing PETG vs PLA filament for printability, PLA Filament takes the lead for ease of use. PLA prints at lower temperatures (typically 180-220°C) and doesn’t need a heated bed, making it accessible for most 3D printers. Warping and adhesion issues are rare.

PETG Filament, while still user-friendly, prints at higher temperatures (220-250°C) and benefits from a heated bed to minimize warping. It can sometimes string or produce little “hairs,” which may require tweaking retraction settings. Still, PETG Filament is less prone to cracking than other tough filaments.

Strength & Durability

If your prints require extra toughness, PETG Filament shines. It’s more impact-resistant and flexible than PLA Filament, making it suitable for mechanical parts, enclosures, or components subjected to stress. On the other hand, PLA Filament offers good rigidity but can snap or deform under pressure, especially at higher temperatures.

Visual Finish & Aesthetics

For a smooth, glossy finish, PLA Filament stands out. It’s available in a wide range of vibrant colors and delivers excellent surface detail, making it perfect for prototypes, figurines, and decorative objects.

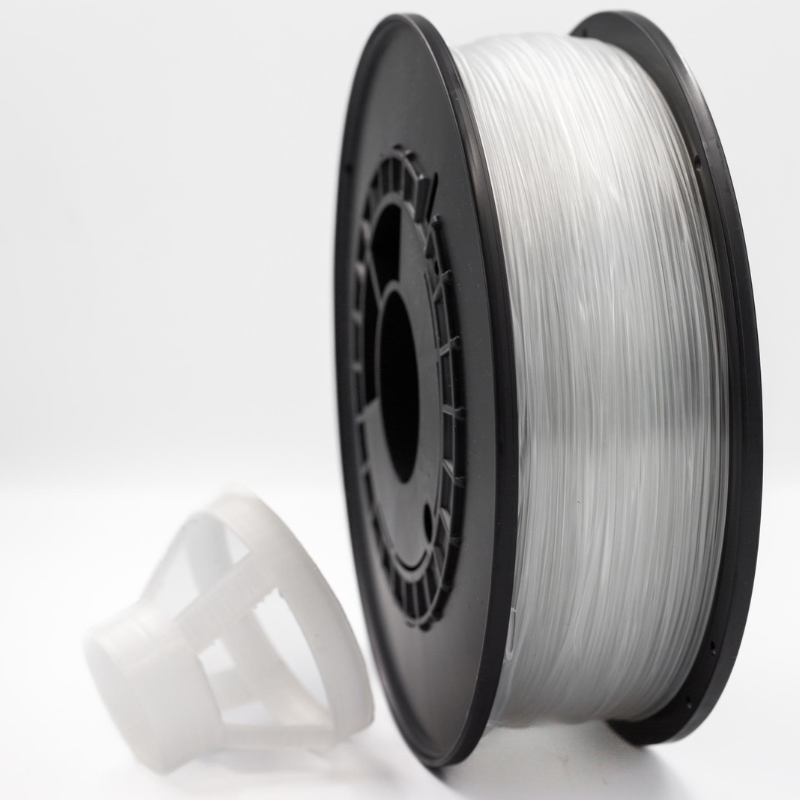

PETG Filament has a subtle sheen and is often available in translucent colors. While it can achieve a nice finish, it’s slightly less crisp than PLA. When considering PETG vs PLA filament for visual appeal, PLA typically comes out on top, especially for models intended for display.

Environmental Factors

Sustainability is increasingly important in the 3D printing world. PLA Filament is biodegradable under industrial composting conditions and made from renewable resources. If you prioritize eco-friendliness, PLA is the clear winner.

PETG Filament is not biodegradable but is recyclable. It excels in outdoor applications, thanks to its resistance to UV, moisture, and chemicals. If your prints need to withstand the elements, PETG Filament may be the better choice.

Cost & Availability

Both PLA Filament and PETG Filament are widely available and competitively priced. However, PLA is generally the more affordable option and comes in more color and specialty variants. PETG is usually slightly more expensive but offers added durability.

Best Applications: When to Use PLA and When to Use PETG

- Choose PLA Filament for:

- Detailed models, educational projects, and decorative pieces

- Rapid prototyping where aesthetics matter most

- Users seeking a low-odor, easy-to-print material

- Choose PETG Filament for:

- Parts requiring strength, flexibility, and chemical resistance

- Outdoor and utility items

- Food-safe applications (with appropriate certification)

The PETG vs PLA filament debate ultimately comes down to your project’s requirements.

Troubleshooting Common Issues

- PLA Filament: May experience brittleness, so avoid storing in damp environments. Rarely warps, but can string if the print head is too hot.

- PETG Filament: Watch for stringing and oozing. Fine-tune your retraction settings and ensure your bed is properly leveled.

Expert Tips for Choosing the Right Filament

When deciding on PLA Filament or PETG Filament, consider your printer’s capabilities, the end-use of your object, and your own experience level. Test both filaments on small prints to see which works best for your projects. Also, always buy quality filament, like the options available at FilaLab.shop, to ensure consistent results.

Conclusion: Which Filament Reigns Supreme for Your 3D Prints?

There’s no absolute winner in the PETG vs PLA filament showdown. Each has its strengths. PLA Filament offers unbeatable printability and gorgeous finishes, making it ideal for beginners and those focused on aesthetics. PETG Filament brings added durability and resilience for functional, demanding prints. By understanding their differences, you’ll confidently select the perfect material for every 3D print. Ready to level up your projects? Explore top-quality PLA and PETG filament at FilaLab.shop and take your creativity to the next level!