Choosing the best filament for printing is more than just picking a spool with the right color or price tag. Every project has unique requirements — from mechanical strength to surface finish — and the wrong choice can lead to weak, warped, or brittle prints. This filament guide will help you confidently navigate the different material options available and match them perfectly to your project’s goals and your printer’s capabilities.

Filament Selection Fundamentals

Key Material Properties to Understand

Before deciding which filament to use, it’s essential to understand how each material behaves during and after printing. The best filament for printing depends on key factors such as:

- Strength and Durability: Some filaments like Nylon or Polycarbonate offer exceptional mechanical strength, ideal for functional parts that endure stress.

- Flexibility and Elasticity: TPU and TPE are popular in flexible designs that require bending or compression.

- Heat Resistance: Materials like ABS or ASA withstand higher temperatures, making them suitable for outdoor or automotive applications.

- Chemical Resistance and Moisture Sensitivity: Some filaments absorb moisture easily, so knowing storage needs is crucial.

- Surface Finish: PLA and PETG deliver smooth, glossy finishes for decorative or prototyping purposes.

This filament guide helps identify these characteristics so you can balance performance, aesthetics, and printability effectively.

Compatibility Considerations

No matter how strong or attractive a filament seems, it must be compatible with your 3D printer. The best filament for printing won’t perform well if your printer can’t handle its temperature or extrusion needs.

- Printer Hardware: Check the extruder’s temperature range, heated bed, and enclosure.

- Nozzle Diameter: Filaments with composite materials (e.g., carbon fiber) may require a hardened steel nozzle.

- Filament Diameter: Whether you use 1.75 mm or 2.85 mm, consistent tolerances ensure steady extrusion.

- Environmental Factors: Humidity can cause stringing or inconsistent extrusion, so keep your filament dry.

Project-Driven Requirements

The filament guide emphasizes evaluating your end goal. Are you printing for function or form? Load-bearing mechanical parts demand materials with high tensile strength, while aesthetic models can use lightweight, glossy PLA. Always align filament choice with your print’s final purpose.

Overview of Popular Filament Types & When to Use Them

PLA (Polylactic Acid)

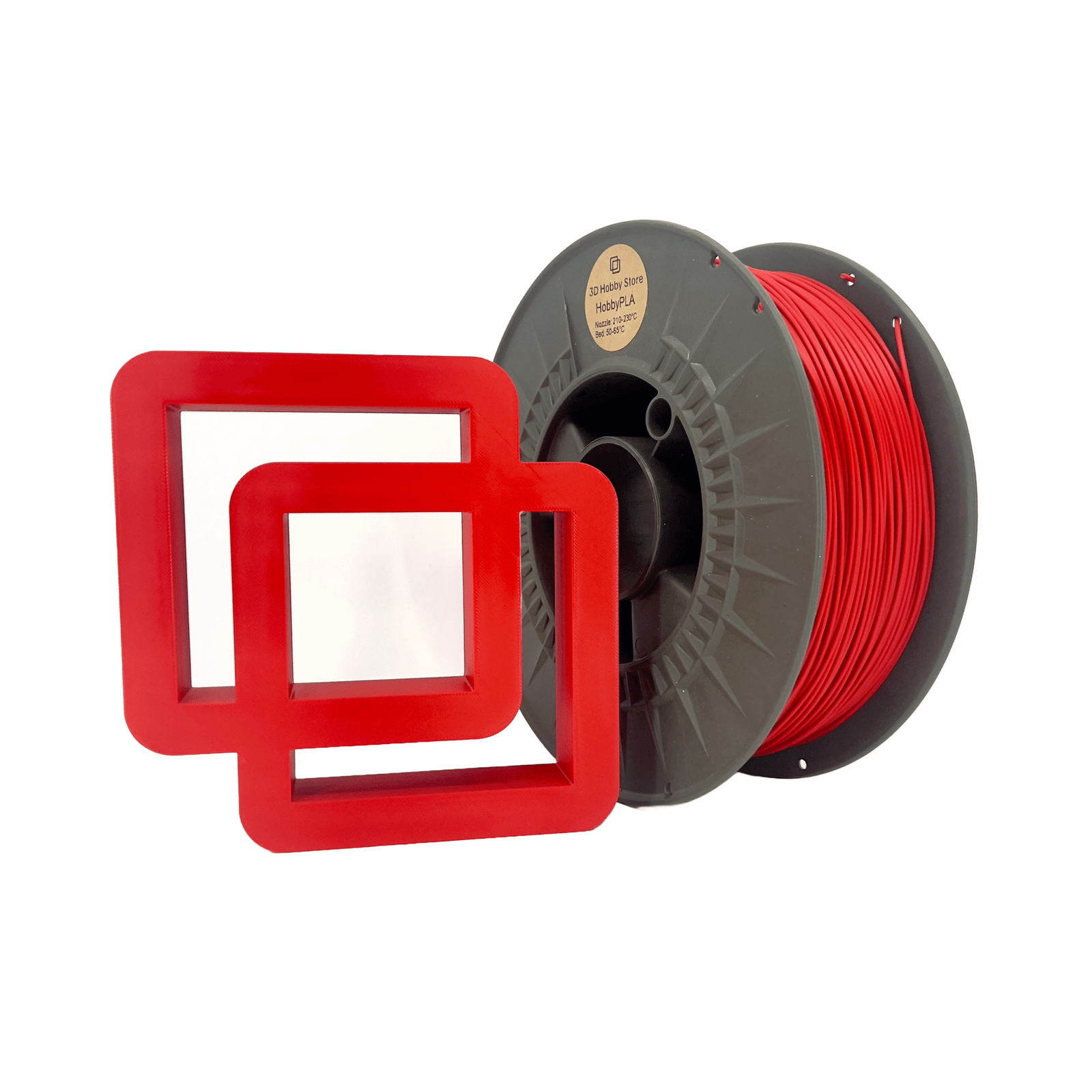

PLA is often considered the easiest and best filament for printing for beginners. It’s biodegradable, affordable, and produces beautiful surface finishes. However, it’s brittle and not ideal for high-heat or mechanical applications.

ABS (Acrylonitrile Butadiene Styrene)

ABS offers better heat resistance and toughness but requires higher extrusion temperatures and careful handling to prevent warping. Use it for durable mechanical parts, tools, or enclosures.

PETG (Polyethylene Terephthalate Glycol)

PETG bridges the gap between PLA and ABS. It’s stronger than PLA, less prone to warping than ABS, and resists impact and chemicals. The filament guide often recommends PETG for household items, containers, and light mechanical parts.

Nylon (Polyamide)

Nylon’s flexibility and strength make it one of the best filaments for printing mechanical components and moving parts. However, it’s very moisture-sensitive and requires controlled printing conditions.

TPU / TPE (Flexible Filaments)

If flexibility is a priority, TPU and TPE are top choices. They’re ideal for phone cases, gaskets, or flexible joints. However, they can be tricky to print without proper retraction settings.

ASA

ASA provides the mechanical strength of ABS but with better UV and weather resistance. The filament guide highlights it for outdoor applications and long-lasting prototypes.

Polycarbonate (PC)

Polycarbonate is incredibly strong and impact-resistant, ideal for engineering applications. However, it demands high printing temperatures and an enclosed printer.

Composite and Specialty Filaments

For advanced users, composites like carbon-fiber-infused or wood-filled filaments provide unique finishes and mechanical advantages. These are considered premium options when exploring the best filament for printing high-performance or artistic models.

Decision Workflow: How to Pick the Right Filament

Step 1 — Define Project Goals

Start by identifying what matters most — strength, flexibility, or appearance. The filament guide recommends writing down your primary goals before browsing materials.

Step 2 — Match with Printer Capability

Your hardware limits your material choices. Ensure your printer’s extruder and bed temperatures match the requirements of the selected filament.

Step 3 — Compare Options

Narrow your list to 2–3 filaments that meet your needs, then compare their printability, cost, and finish quality.

Step 4 — Test and Adjust

The best filament for printing might still need fine-tuning. Always print small test models first to adjust temperature, speed, or cooling settings.

Practical Tips & Best Practices

Storage & Moisture Control

Proper filament storage maintains performance. Use airtight containers or filament dryers to keep moisture-sensitive materials like Nylon or PETG in prime condition.

Adjusting Print Settings

Each material reacts differently to changes in speed, temperature, and cooling. The filament guide suggests experimenting within manufacturer-recommended ranges for perfect results.

Avoiding Common Problems

- Warping: Use heated beds or enclosures for ABS and ASA.

- Stringing: Fine-tune retraction for PETG or TPU.

- Brittleness: Dry filament before printing to restore flexibility and strength.

Material Comparison Summary

| Material | Strength | Flexibility | Heat Resistance | Ease of Printing | Ideal Use |

|---|---|---|---|---|---|

| PLA | Medium | Low | Low | Very Easy | Decorative, Prototypes |

| ABS | High | Medium | High | Moderate | Tools, Enclosures |

| PETG | High | Medium | Medium | Easy | Household Items |

| Nylon | Very High | High | High | Hard | Mechanical Parts |

| TPU | Low | Very High | Low | Medium | Flexible Products |

| ASA | High | Medium | Very High | Moderate | Outdoor Parts |

This quick comparison simplifies the process of identifying the best filament for printing according to project needs and printer specifications.

Conclusion

Selecting the right filament doesn’t have to be overwhelming. With this filament guide, you now know what to evaluate — from mechanical strength and printer compatibility to print environment and desired finish. The best filament for printing is the one that matches your specific project’s purpose, materials, and design expectations. Experiment, take notes, and refine your approach — because mastering filament choice is the foundation of mastering 3D printing itself.