DIY 3D Printing Sustainability: How to Recycle PETG & PLA at Home Without Breaking the BankRecycling your own 3D printing waste might sound like a professional task requiring industrial machinery, but it doesn’t have to be. With some creativity, patience, and basic equipment, makers can recycle PETG and PLA filaments right from home — without spending a fortune. Let’s explore how to turn your discarded prints and support structures into usable filament again, saving money and reducing waste in the process.

Understanding PETG & PLA Recycling (Basics)

What Are PETG and PLA — and How Do They Differ?

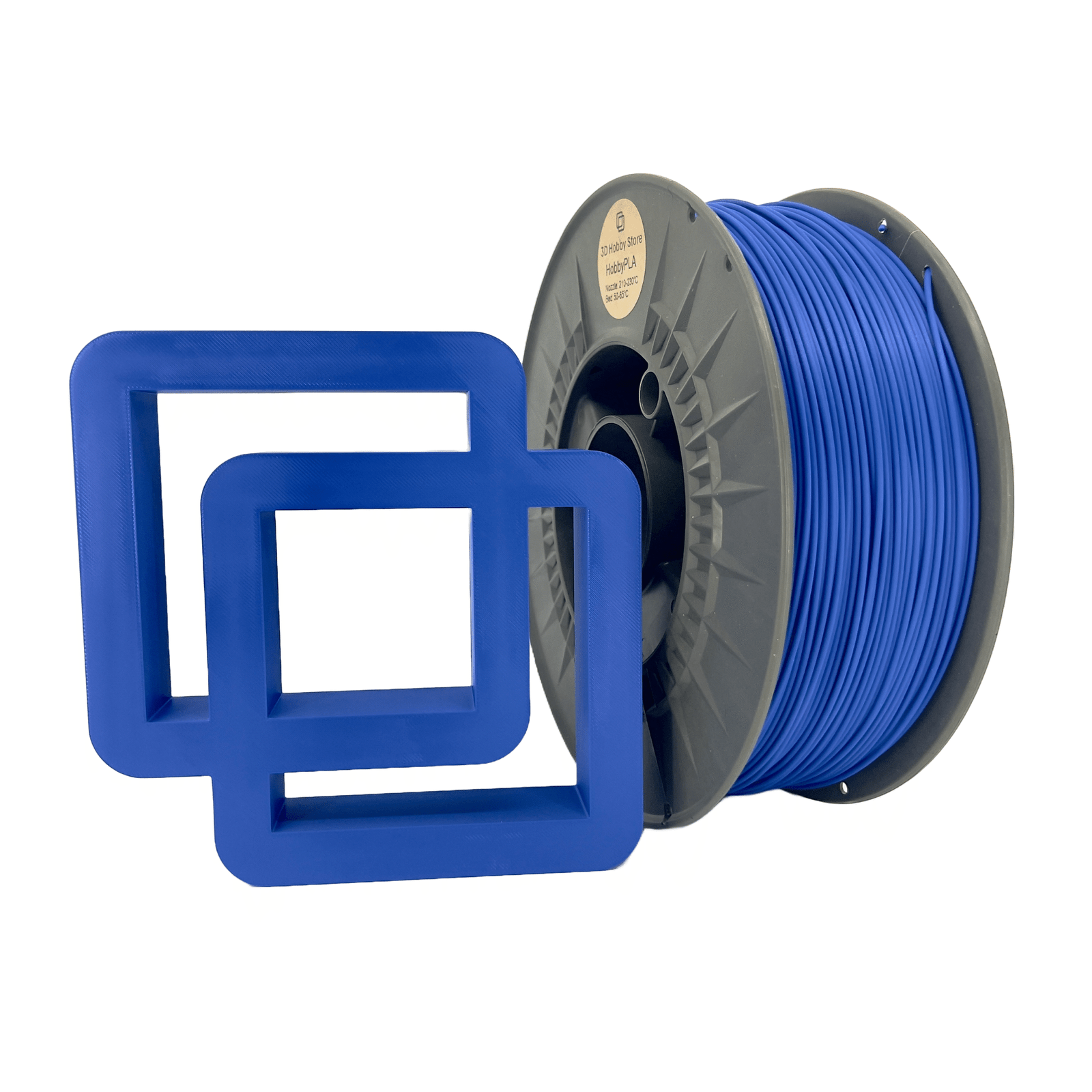

PLA (Polylactic Acid) is a biodegradable, plant-based plastic known for its ease of printing and low melting temperature. PETG (Polyethylene Terephthalate Glycol), on the other hand, is a more durable, impact-resistant material that withstands heat and stress better. These properties make PETG ideal for functional parts but also make it slightly more complex to recycle at home because it needs higher extrusion temperatures and careful drying.

Why Recycling 3D Print Waste Is Important

Every spool of filament used adds to plastic waste, especially when misprints and supports pile up. Recycling 3D print waste helps close the loop by turning scrap into new filament instead of throwing it away. For makers and hobbyists, it’s both an environmental and financial advantage: less landfill waste, lower material costs, and the satisfaction of sustainability.

Common Stumbling Blocks in Home Recycling

Home recycling isn’t always smooth sailing. Moisture absorption can cause bubbling during extrusion, while contaminants such as dust or leftover glue compromise print quality. Consistent filament diameter is another challenge, but with patience and testing, you can produce surprisingly high-quality results.

Low-Cost Tools & Methods You Can Use at Home

Shredding or Grinding Without Industrial Equipment

To recycle your old prints, you first need to break them down into smaller pieces. While industrial shredders are expensive, there are affordable alternatives. Modified kitchen blenders, hand-cranked grinders, or even small woodworking shredders can be used to grind your plastic waste safely. Just make sure to use eye protection and avoid overheating the material, as melting during grinding can ruin it.

Drying the Plastic Fragments

Both PLA and PETG are hygroscopic, meaning they absorb moisture from the air. Drying the shredded plastic before melting is crucial. You can use a household oven set to 50–60°C, a food dehydrator, or silica-gel-based storage boxes. Even simple DIY setups, like an airtight container with reusable desiccant packs, can work effectively. Proper drying ensures that your recycled filament extrudes smoothly without air bubbles.

Melt-Extruding on a Budget

Once dried, the plastic is ready for extrusion. You don’t need an industrial-grade extruder — several open-source or desktop models like Filastruder or Felfil Evo are available at lower costs. You can even build a DIY filament extruder using an auger screw and heater band assembly. The trick is maintaining consistent temperature control: around 190–210°C for PLA and 230–250°C for PETG. Keep a close eye on flow speed to avoid diameter fluctuations.

Spooling & Finishing

After extrusion, the filament should cool evenly and wind onto a spool. Many makers use a simple motorized winder setup made from 3D-printed parts, an old stepper motor, and a tension guide. Measuring filament diameter periodically helps ensure consistency. Smooth spooling prevents tangling and guarantees even feeding during printing.

Workflow & Best Practices for Home Recycling Loops

Sorting & Pre-Testing Your Scrap

Never mix PLA and PETG in the same batch. PETG melts at higher temperatures, and blending it with PLA leads to inconsistent filament. Identify materials by their transparency, stiffness, or a quick burn test (PLA burns sweetly, PETG burns with minimal odor). Sorting ensures your output remains consistent and reliable.

Batch Size & Incremental Runs

Start small. Recycling 100–200 grams of scrap lets you experiment with extrusion speeds and cooling rates. Once you master smaller batches, scaling up becomes much easier. If your filament comes out brittle or uneven, regrind it and mix with fresh material to improve quality.

Troubleshooting Tips

- Brittle filament: Too dry or overheated — reduce extrusion temperature slightly.

- Bubbly filament: Moisture problem — dry the plastic again.

- Inconsistent diameter: Adjust feed rate or add a filament guide to the extruder.

Filtering particles through a fine metal mesh before extrusion can also help achieve a cleaner finish.

Case Studies & Real-World Examples

Low-Budget Maker Success Stories

Many hobbyists on platforms like Reddit’s r/3Dprinting share success stories of turning waste prints into usable filament using self-built extruders. One maker reported producing a 1 kg spool of PLA for under $5 in total costs. The secret? Controlled temperature, patient calibration, and a willingness to fail a few times before succeeding.

Home Recycling vs Commercial Recycled Filament

Commercially recycled filament, such as those offered by sustainable brands, ensures professional-grade consistency. However, it’s more expensive and less personal. Home recycling, while variable in quality, provides independence and the satisfaction of contributing to sustainability in a hands-on way.

Safety, Maintenance & Longevity

Safety Precautions While Heating and Shredding

Always work in a well-ventilated area, especially when heating plastics. Wear gloves, safety glasses, and avoid inhaling fumes. Keep fire safety tools nearby and use heat-resistant surfaces.

Maintaining Your Home Recycling Setup

After each session, clean the extruder thoroughly. Remove leftover melted plastic before it hardens, as buildup can lead to blockages and uneven flow. Regularly check bearings, auger screws, and nozzles for wear.

How Long Can Recycled Filament Last?

PLA can be recycled 1–2 times before it loses too much structural integrity, while PETG generally lasts longer. Store your recycled filament in airtight containers with desiccant to extend its shelf life.

When to Use External Recycling or Commercial Filaments

If your setup struggles with consistent results, consider mixing home-recycled filament with commercial material. This blend balances sustainability and performance. For large-scale projects or professional applications, it may be more efficient to buy high-quality recycled filaments from trusted suppliers like Filamentive.

Conclusion

Recycling PETG and PLA at home doesn’t demand an expensive setup — just creativity, care, and a bit of experimentation. By mastering simple tools and understanding the properties of each filament, makers can reduce waste, cut costs, and make 3D printing more sustainable. Start small, stay safe, and share your journey — because every spool you recycle makes a real impact on our planet’s future.