In today’s world of advanced manufacturing, professionals are under increasing pressure to balance productivity, innovation, and sustainability. As the focus on environmental responsibility sharpens, understanding and reducing the carbon footprint of additive manufacturing (AM)—or 3D printing—has become essential. If you’re looking for actionable strategies to minimize emissions, check out this guide on how recycled materials can reduce CO2 emissions in 3D printing for practical tips. But before diving into reduction tactics, it’s crucial to master the basics of carbon accounting tailored specifically for the AM sector.

What is Carbon Accounting and Why Does It Matter?

Carbon accounting is the systematic process of measuring, tracking, and reporting greenhouse gas (GHG) emissions generated by business activities. For additive manufacturing, carbon accounting isn’t just a box to check—it’s a core element of responsible operation, as AM technologies increasingly shape supply chains, product development, and even end-of-life recycling.

Understanding your operation’s carbon footprint allows you to:

- Pinpoint major emission sources

- Identify opportunities to reduce energy and material waste

- Comply with tightening global regulations and industry standards

- Enhance your reputation among eco-conscious customers and partners

The ABCs of Carbon Emissions: Scope 1, 2, and 3

To truly understand carbon accounting, you’ll need to get comfortable with its key categories:

- Scope 1: Direct emissions from sources you own or control, such as on-site fuel combustion for your printers or post-processing units.

- Scope 2: Indirect emissions from purchased electricity, heat, or steam used to power your facilities.

- Scope 3: All other indirect emissions, including those from material production, product transportation, supply chains, and product end-of-life.

For additive manufacturing, Scope 2 (electricity use for printers) and Scope 3 (upstream material sourcing) often represent the biggest emission contributors.

Unique Challenges in Additive Manufacturing

Additive manufacturing offers unique sustainability advantages over traditional methods, such as minimized waste and efficient use of raw materials. However, AM is not inherently “green”—its carbon profile depends heavily on:

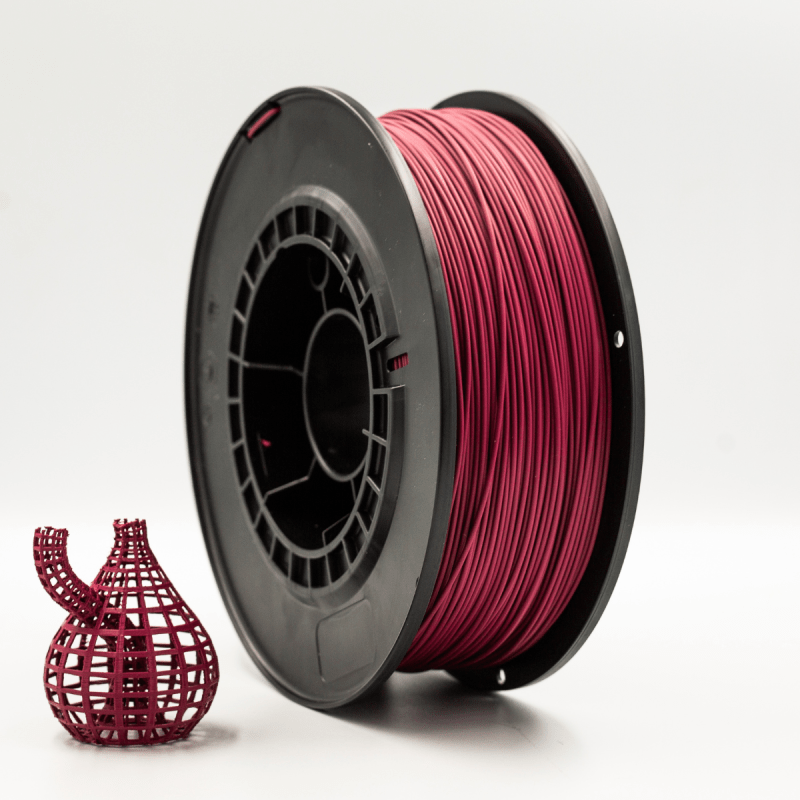

- Material Choices: Virgin polymers, metals, and specialty filaments can carry significant embodied emissions, while recycled materials can dramatically lower the footprint.

- Energy Consumption: Some 3D printers, especially those using high-powered lasers or extensive post-processing, draw substantial energy from the grid.

- Logistics and Distribution: Digital inventory and localized production can reduce transport emissions, but shipping feedstock and finished goods still counts.

How to Measure Your Carbon Footprint in AM

Carbon accounting might sound daunting, but it’s more accessible than ever:

- Data Collection: Start by gathering data on electricity use, material quantities, waste output, and transportation distances. Smart meters, digital production logs, and supplier data are valuable tools.

- Calculations and Tools: Use recognized frameworks such as the Greenhouse Gas Protocol or ISO 14064. There are also industry-specific software solutions that can automate much of the process.

- Reporting: Summarize your emissions in a clear, consistent manner, noting assumptions and boundaries. Transparency helps build credibility with customers and regulators.

Quick Example:

If your shop runs four FDM printers drawing 2 kWh each for 10 hours per day, that’s 80 kWh daily. Multiply this by your local grid’s emission factor to estimate your Scope 2 emissions. Then, add emissions associated with the production and transport of your filament (Scope 3) and any on-site fuel combustion (Scope 1).

Strategies for Reducing Your AM Carbon Footprint

Effective carbon management is about progress, not perfection. Here are actionable strategies:

- Switch to Recycled Materials: As detailed in the Filalab guide, using recycled filaments can substantially reduce both Scope 3 emissions and overall CO2 output.

- Source Renewable Energy: Transitioning to solar, wind, or other renewables for facility power significantly shrinks Scope 2 emissions.

- Optimize Designs: Leverage AM’s design freedom to create lightweight, material-efficient components—reducing both production emissions and shipping weight.

- Implement Efficient Post-Processing: Minimize the use of energy- or solvent-intensive finishing steps.

- Reduce Waste: Collect and recycle support material, failed prints, and end-of-life parts whenever possible.

The Regulatory and Market Context

Governments and industry bodies are ramping up carbon disclosure requirements, especially for technology and manufacturing sectors. Voluntary standards like Environmental Product Declarations (EPDs) and certifications such as ISO 14064 are fast becoming market expectations.

Meeting these standards not only ensures compliance but also positions your company as a leader in sustainability—a major differentiator for clients, investors, and procurement officers.

The Business Value of Carbon Accounting

Beyond regulatory compliance, carbon accounting can deliver real business benefits:

- Cost Reduction: Energy and material efficiency often translates to lower operational costs.

- Market Access: Many large buyers now require carbon data from suppliers.

- Brand Reputation: Transparent reporting strengthens trust and appeal, especially among environmentally aware customers.

- Future-Proofing: Anticipating carbon-related risks prepares you for tighter future regulations and market shifts.

Conclusion: The Future of Sustainable AM

As additive manufacturing matures, sustainability and carbon accountability will only grow in importance. By embracing carbon accounting now—leveraging recycled materials, renewable energy, and smart data tracking—AM professionals can drive both environmental progress and business success.

Whether you’re just starting out or optimizing an established operation, make carbon accounting part of your standard toolkit. The future of responsible, competitive manufacturing depends on it