Can You Mix Recycled and Virgin Filaments in One 3D Print?

The question can you mix recycled and non recycled filament in a single print is becoming more common as sustainability meets performance-driven 3D printing. Many makers want to reduce waste by using recycled materials, yet still rely on virgin filament for strength, consistency, or surface quality. In practice, it is technically possible to mix recycled and virgin filament in one print, but the outcome depends heavily on material compatibility, print settings, and how the filaments are used within the part.

When evaluating whether you should mix recycled and virgin filament, it is important to understand that recycled filament vs virgin filament is not simply a question of “good or bad.” Each has distinct material behaviors, and combining them introduces new variables that must be controlled carefully.

What “Recycled” and “Virgin” Filaments Really Mean in 3D Printing

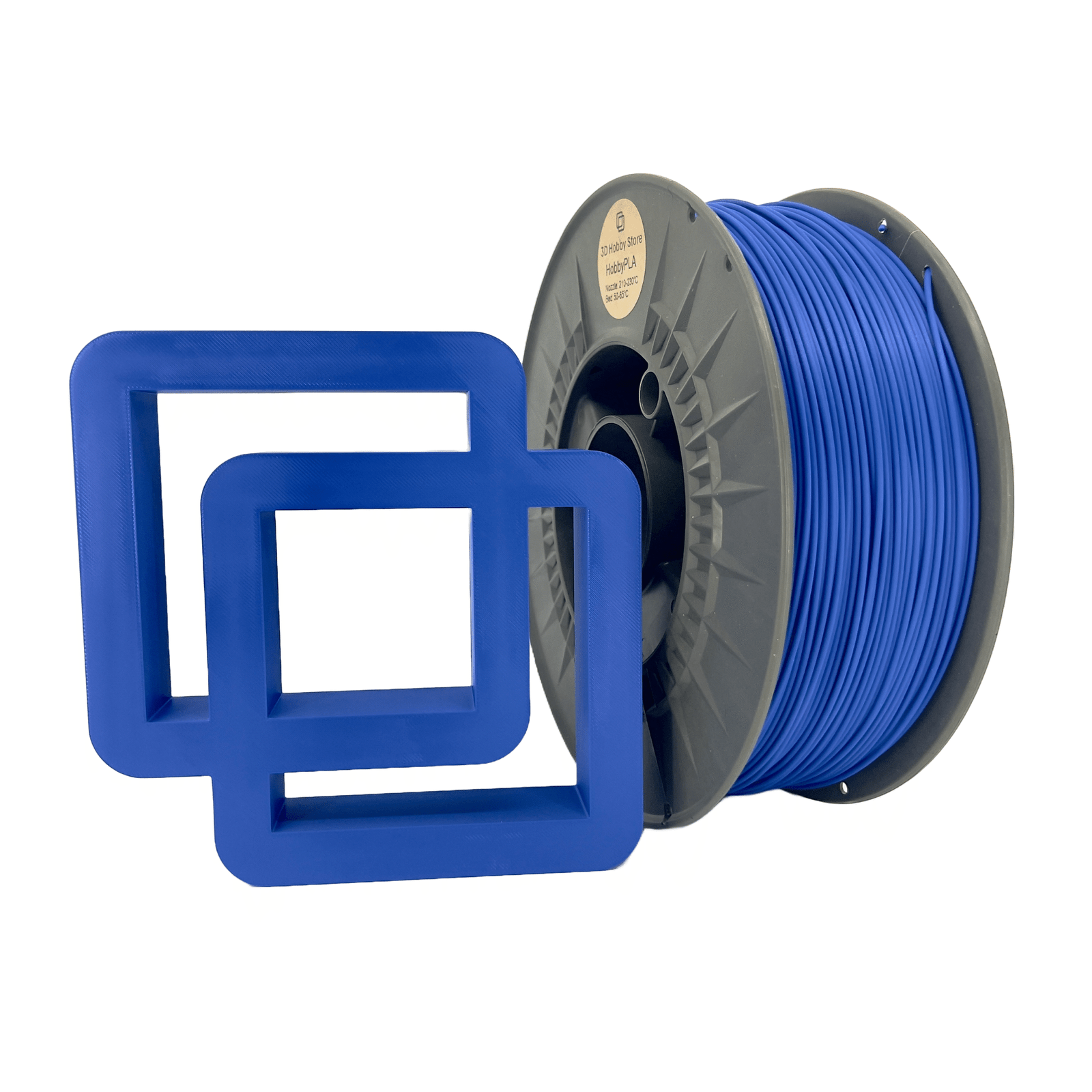

Virgin filament is produced from newly synthesized polymers with tightly controlled material properties. Diameter consistency, melt flow, and mechanical strength are usually predictable. Recycled filament, on the other hand, is made from reprocessed plastic waste or production scraps. While high-quality recycled filament can perform very well, it often shows greater variation in melt flow index, stiffness, and color consistency.

Understanding recycled filament vs virgin filament at a material level is essential before attempting to mix recycled and virgin filament in one part. The polymers may be the same chemically, but their thermal and mechanical histories are not.

Why Makers Consider Mixing Recycled and Non-Recycled Filaments

There are three main reasons why users ask can you mix recycled and non recycled filament in a single print. The first is sustainability, as recycled filament reduces plastic waste and lowers environmental impact. The second is cost, since recycled filament is often more affordable. The third is functional optimization, where recycled filament is used for internal structures and virgin filament is reserved for outer walls or stress-critical zones.

Common Filament Types Where Mixing Is Most Attempted (PLA, PETG, ABS)

Mixing is most commonly attempted with PLA, PETG, and ABS because recycled versions of these materials are widely available. PLA is the easiest to experiment with due to its low warping and forgiving print temperatures. PETG introduces more challenges due to stringing and flow differences. ABS is the most sensitive, as recycled ABS often has higher shrinkage variability.

Material Compatibility: What Happens When You Mix Them

Differences in Melt Flow Index Between Recycled and Virgin Filaments

One of the biggest technical challenges when you mix recycled and virgin filament is melt flow mismatch. Recycled filament often flows more easily due to polymer chain degradation during recycling. This means that when switching from virgin filament to recycled filament, over-extrusion can occur if flow rates are not adjusted.

In recycled filament vs virgin filament comparisons, melt flow index differences are often the root cause of inconsistent layer widths and surface artifacts.

Layer Adhesion Risks When Switching Materials Mid-Print

Layer adhesion can suffer when you mix recycled and virgin filament, especially if the switch happens in load-bearing regions. Even if both filaments are PLA, differences in thermal bonding can create weak interfaces. This is why understanding can you mix recycled and non recycled filament safely depends on where the transition occurs within the print.

Thermal Behavior and Shrinkage Variations

Recycled filament often has less predictable shrinkage behavior. When combined with virgin filament, internal stresses can form as the print cools. These stresses may not be visible immediately but can reduce long-term durability.

Color, Texture, and Surface Finish Inconsistencies

Visual differences are unavoidable when you mix recycled and virgin filament. Recycled filament often has matte finishes or slight color variations, while virgin filament tends to look more uniform. For functional parts this may not matter, but for consumer-facing prints it often does.

Mechanical Strength and Print Performance Impacts

Tensile Strength Differences Across Mixed Layers

In recycled filament vs virgin filament comparisons, virgin material typically offers higher tensile strength. When you mix recycled and virgin filament, tensile strength becomes uneven across the Z-axis. This is particularly relevant for parts under bending or tension.

How Recycled Content Affects Impact Resistance

Recycled filament can be more brittle due to shortened polymer chains. When mixed improperly, impact resistance may drop significantly at transition layers. This is why asking can you mix recycled and non recycled filament must always be paired with an understanding of mechanical demands.

Load-Bearing and Structural Limitations

For structural parts, mixing materials is risky unless the recycled filament is confined to non-critical areas. Using recycled filament for infill and virgin filament for perimeters is a common compromise.

Real-World Stress Points Where Failure Is Most Likely

Failures usually occur at material transition zones, sharp corners, and thin walls. If you mix recycled and virgin filament, these areas must be designed carefully.

Printing Setup Considerations Before Mixing Filaments

Nozzle Temperature Adjustments for Hybrid Prints

Recycled filament often requires slightly lower nozzle temperatures. When switching between materials mid-print, temperature transitions must be gradual to avoid thermal shock.

Bed Temperature and Adhesion Strategy Changes

Differences in bed adhesion behavior are another challenge when you mix recycled and virgin filament. Using a universal adhesion solution such as PEI sheets or adhesive sprays can help stabilize results.

Retraction, Cooling, and Flow Rate Tuning

Flow rate tuning is essential when working with recycled filament vs virgin filament combinations. Cooling may also need adjustment, as recycled filament can solidify faster.

Multi-Extruder vs Single-Extruder Printing Scenarios

Multi-extruder systems make it easier to control material transitions. Single-extruder systems rely on filament swaps, which increase the risk of contamination and weak layers.

Best Practices for Mixing Recycled and Virgin Filaments

When to Use Recycled Filament for Internal Structures

The safest approach is to use recycled filament for infill or internal ribs. This allows you to benefit from sustainability without compromising surface quality or strength.

When Virgin Filament Is Better for Outer Shells

Virgin filament should be used for outer walls, threads, snap-fits, and load-bearing surfaces. This strategy addresses the main concerns behind can you mix recycled and non recycled filament safely.

Safe Layer Transition Techniques

Gradual transitions, purge towers, and overlap zones can reduce weakness at material boundaries. Avoid abrupt switches in critical layers.

Recommended Print Speeds and Layer Heights

Slower print speeds and moderate layer heights improve bonding when you mix recycled and virgin filament. Thin layers increase the number of transition points, which can weaken the part.

Sustainability vs Performance: Finding the Right Balance

Environmental Benefits of Using Recycled Filament

Recycled filament reduces landfill waste and lowers carbon footprint. For non-critical parts, the environmental advantages often outweigh minor performance losses.

Performance Trade-Offs You Should Expect

When comparing recycled filament vs virgin filament, expect reduced consistency and slightly lower mechanical strength. These trade-offs are manageable with good design.

Cost Efficiency and Material Waste Reduction

Mixing materials can significantly reduce filament costs, especially for large prints. Using recycled filament strategically minimizes waste without sacrificing quality.

When Sustainability Makes Sense for Functional Parts

Sustainability makes sense when loads are predictable and safety margins are high. For safety-critical parts, virgin filament remains the safer choice.

Common Mistakes to Avoid

Mixing Filaments With Different Base Polymers

Never mix PLA with PETG or ABS, even if both are recycled. Chemical incompatibility will cause delamination.

Ignoring Moisture Content Differences

Recycled filament often absorbs more moisture. Drying both materials before printing is essential.

Skipping Calibration Prints

Calibration prints help identify flow and temperature differences before committing to a full build.

Overlooking Long-Term Part Durability

Parts printed with mixed materials may degrade faster over time, especially in outdoor or high-temperature environments.

Real Use Cases and Practical Examples

Prototyping and Visual Models

Prototypes are ideal candidates for mixing materials. Minor strength differences are usually acceptable.

Jigs, Fixtures, and Low-Stress Components

Workshop tools and fixtures benefit greatly from mixed-material printing.

Educational and Hobbyist Projects

Learning environments are perfect for experimenting with recycled filament vs virgin filament combinations.

Why Critical Engineering Parts Need Material Consistency

For aerospace, automotive, or safety-critical components, material consistency is non-negotiable.

Final Verdict: Should You Mix Recycled and Virgin Filaments in One Print?

Who Should Consider It and Who Should Not

If sustainability, cost reduction, or experimentation is your goal, you can mix recycled and virgin filament successfully with proper setup. If reliability and certification are required, mixing is not recommended.

Key Takeaways for Reliable Hybrid Printing

The answer to can you mix recycled and non recycled filament is yes, but only with intention. Understanding recycled filament vs virgin filament differences, controlling print parameters, and choosing smart material placement are the keys to success. When done correctly, mixing materials can deliver functional, sustainable, and cost-effective 3D prints without compromising reliability.