Introduction

In the world of 3D printing, basic PLA has long been the go-to filament for both beginners and professionals. But as newer, enhanced versions like PLA+ rise in popularity, a question emerges — can standard PLA still hold its own in 2025? To find out, we tested basic PLA across three different print types — a functional mechanical part, a decorative model, and a large-format print. The goal was simple: to uncover whether PLA vs PLA+ truly shows a big difference in performance, or if the affordable classic still delivers great results for everyday printing needs.

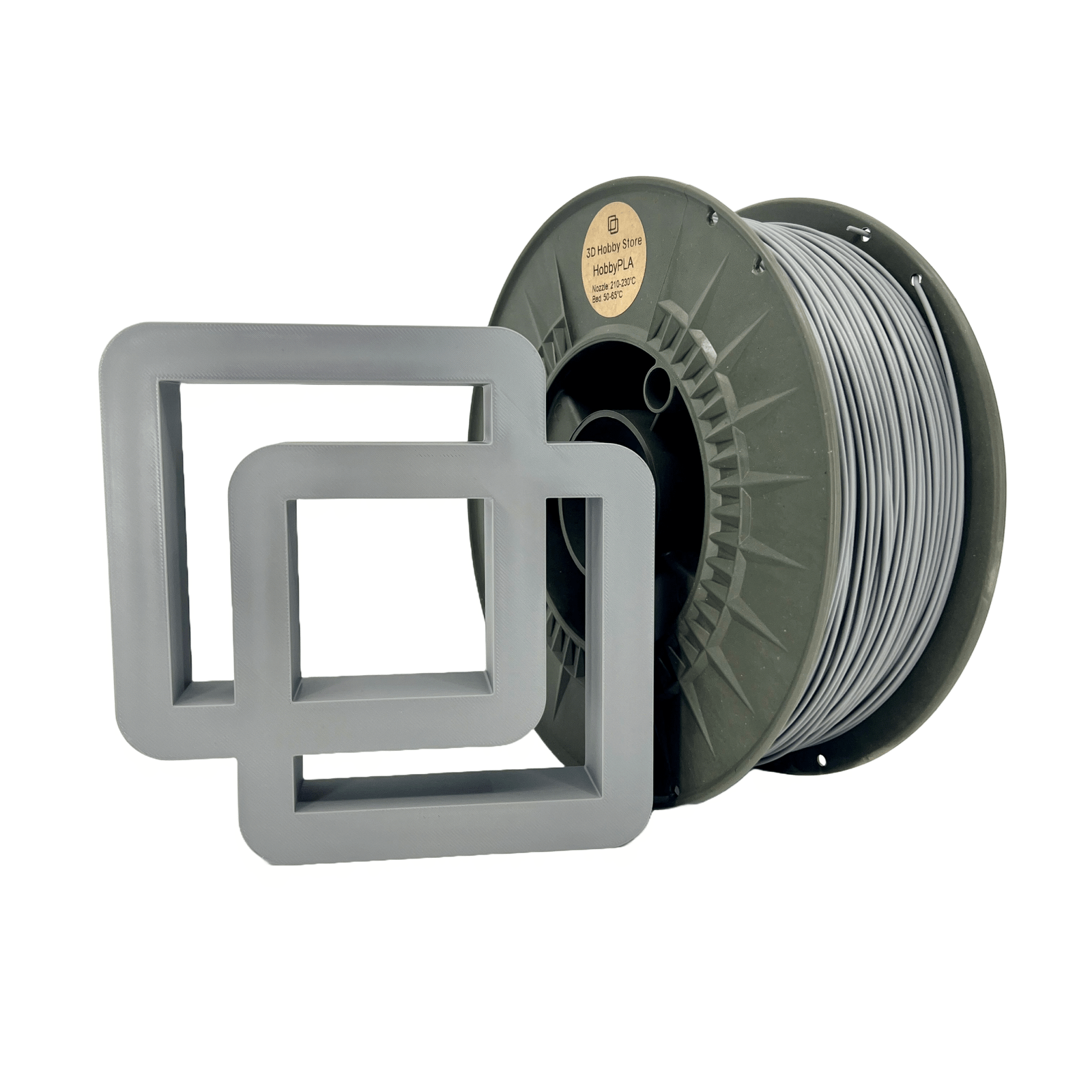

What Is Basic PLA Filament?

Polylactic Acid (PLA) is a biodegradable thermoplastic derived from renewable sources like corn starch or sugarcane. Known for its ease of use, minimal warping, and low print temperature, PLA has become a staple in FDM 3D printing. When discussing PLA vs PLA+, it’s important to understand that PLA+, or PLA Plus, is a modified version of standard PLA with added polymers or impact modifiers that improve flexibility, strength, and heat resistance. In other words, PLA+ vs PLA can be summed up as a trade-off between simplicity and enhanced performance. While PLA Plus may offer superior mechanical properties, basic PLA often provides consistent results for standard prints — especially when tuned correctly.

Why Use Basic PLA? Advantages at a Glance

The enduring appeal of basic PLA lies in its accessibility and reliability. For new makers, it’s an excellent starting point because: Ease of printing: It adheres well to most print beds and requires minimal tuning. Affordability: Compared to PLA Plus, it’s often 10–20% cheaper, making it perfect for prototypes and high-volume projects. Eco-friendly nature: Since it’s made from renewable resources, it’s one of the most sustainable options on the market. These qualities make it ideal for projects where extreme strength isn’t necessary. The key, however, is knowing where basic PLA’s limits lie — especially when comparing PLA vs PLA+ in real printing conditions.

Limitations of Basic PLA — What to Be Aware Of

Although standard PLA prints easily, it’s not flawless. It’s more brittle than PLA Plus, which can limit its use for mechanical parts or components exposed to heat. Its low glass transition temperature (around 60°C) means it may deform under direct sunlight or frictional heat. When examining PLA+ vs PLA, many users find that PLA Plus can withstand slightly higher temperatures and endure more stress before breaking. For decorative models or lightweight prototypes, though, these limitations are rarely an issue — which is why we put both through real tests to see where the performance gap truly matters.

Testing Methodology — How We Evaluated Basic PLA Across Three Print Types

We designed three different tests using a Prusa MK3S+ and a Creality Ender 3 V3 SE to compare the printability and quality of basic PLA under varied conditions. Each test used the same slicing profile except for minor adjustments in temperature and speed: 1. Functional mechanical part – A load-bearing bracket tested for flex and strength. 2. Decorative model – A complex vase emphasizing fine details and surface smoothness. 3. Large-format print – A 200mm prototype shell testing consistency and adhesion. Our evaluation criteria included surface quality, dimensional accuracy, ease of print, and durability after printing.

Test Results: Functional Mechanical Part

When it came to the functional bracket, basic PLA performed surprisingly well up to moderate loads. Layer adhesion was solid, and dimensional accuracy was within ±0.1 mm. However, compared to PLA Plus, the printed bracket fractured more easily under repeated bending. This reinforced the typical finding in the PLA vs PLA+ debate — PLA+ offers improved flexibility and impact resistance, making it the better choice for parts under mechanical stress. Still, if your functional parts don’t require repeated strain, basic PLA remains perfectly viable.

Test Results: Decorative/Aesthetic Model

In the decorative test, basic PLA outshone its upgraded sibling. The vase printed with excellent precision, glossy finish, and no visible stringing. The color vibrancy of PLA Plus was slightly deeper, but the visual clarity and detail reproduction were superior with basic PLA. Here, the PLA+ vs PLA difference became less about strength and more about surface texture and consistency. For artistic prints, basic PLA still offers a premium look without the extra cost.

Test Results: Large-Format Print

The large shell print was the most demanding test. Basic PLA exhibited mild warping and a few layer inconsistencies beyond 150 mm in height. By contrast, PLA Plus maintained steadier performance throughout the entire print. This is a classic example of where PLA Plus earns its reputation — it’s more tolerant of longer print times and subtle temperature shifts. Still, with proper cooling and adhesion tuning, basic PLA can achieve nearly identical results at a lower material cost.

Comparative Summary — Performance Across All Three Print Types

| Print Type | Basic PLA Performance | PLA Plus Performance | Verdict |

|---|---|---|---|

| Functional Part | Good but brittle | Excellent durability | PLA+ wins |

| Decorative Model | Superior detail and shine | Slightly duller finish | PLA wins |

| Large Print | Occasional warping | Consistent stability | PLA+ wins |

| Overall, the PLA vs PLA+ comparison proves that the choice depends on your project’s priorities. If visual appeal and ease of printing matter most, go with basic PLA. If you need functional strength, PLA Plus is worth the upgrade. |

Practical Tips for Getting the Best from Basic PLA

Even without enhancements, basic PLA can produce impressive results when handled right: Print temperature: 195–210°C, depending on brand. Bed temperature: 50–60°C with glue stick or PEI surface for best adhesion. Cooling: Use 100% fan speed for overhangs and tall prints. Storage: Keep PLA in a dry box — moisture quickly affects print quality. When comparing PLA+ vs PLA, these minor optimizations can often close much of the gap in surface quality and reliability.

When to Upgrade from Basic PLA

If you’re consistently printing functional parts or components exposed to heat, upgrading to PLA Plus is a smart move. Its toughness and temperature resistance justify the slightly higher price. However, for prototyping, artistic pieces, or educational models, basic PLA is still unbeatable for cost and consistency. Think of PLA vs PLA+ not as a competition but as a spectrum: PLA offers accessibility, while PLA Plus provides durability. The right choice depends entirely on what you’re printing.

Conclusion

After testing across three print types, one thing is clear — basic PLA still delivers great results when used for the right applications. It remains smooth, reliable, and beginner-friendly, while PLA Plus shines in more demanding, mechanical projects. The PLA+ vs PLA debate ultimately comes down to priorities: do you value perfect aesthetics and affordability or enhanced strength and heat tolerance? Whatever you choose, both materials continue to push 3D printing forward — proving that even the most basic filament still has a lot to offer in a world of endless innovation.