PLA filament has quickly become the go-to material for anyone exploring the creative possibilities of 3D pens. From kids experimenting with their first designs to professional artists crafting intricate models, PLA offers an ideal balance of ease of use, safety, and precision. In this guide, we’ll explore everything you need to know about using PLA filament for 3D pens—covering best practices, safety tips, and advanced techniques to help you create smooth, detailed, and durable results every time.

Understanding PLA Filament Basics

What Is PLA and Why Use It for 3D Pens

PLA (Polylactic Acid) is a biodegradable thermoplastic derived from renewable resources like corn starch or sugarcane. It’s one of the safest and easiest filaments to work with, especially in 3D pens. Its low melting temperature (around 180–200°C) means it extrudes smoothly without requiring extreme heat, making it ideal for both children and adults.

Advantages and Limitations of PLA in Pen Use

The biggest advantages of PLA are its minimal odor, quick cooling, and bright, consistent color output. It’s also known for its rigidity, allowing you to draw stable structures that hold their form. However, PLA is less heat-resistant than ABS or PETG, meaning finished models should be kept away from heat sources.

Safety & Environmental Considerations

PLA is a non-toxic and eco-friendly filament that releases little to no harmful fumes. This makes it safe for kids under adult supervision. Always ensure your workspace is well-ventilated and avoid touching the hot nozzle during or after use.

Choosing the Right PLA Filament

Diameter & Tolerance (1.75 mm vs 2.85 mm)

Most 3D pens use 1.75 mm PLA filament, which provides better flow control and compatibility. Always check the manufacturer’s specifications before purchasing. Even small variations in diameter tolerance can cause clogging, so choosing a filament with ±0.02 mm consistency ensures smoother operation.

Quality Factors: Purity, Additives, Colorants

Opt for filaments made from pure PLA without excess additives. Low-quality PLA often includes fillers that lead to uneven melting. High-quality brands also offer rich pigments that give your prints a professional look.

Specialty PLA Types (Glow-in-the-Dark, Flexible, Composite Blends)

PLA comes in exciting variations—like silk PLA for glossy finishes, wood or metal composites for texture, and flexible PLA for bendable designs. Kids can enjoy glow-in-the-dark filaments for creative nighttime projects, while professionals can explore composite blends for unique artistic effects.

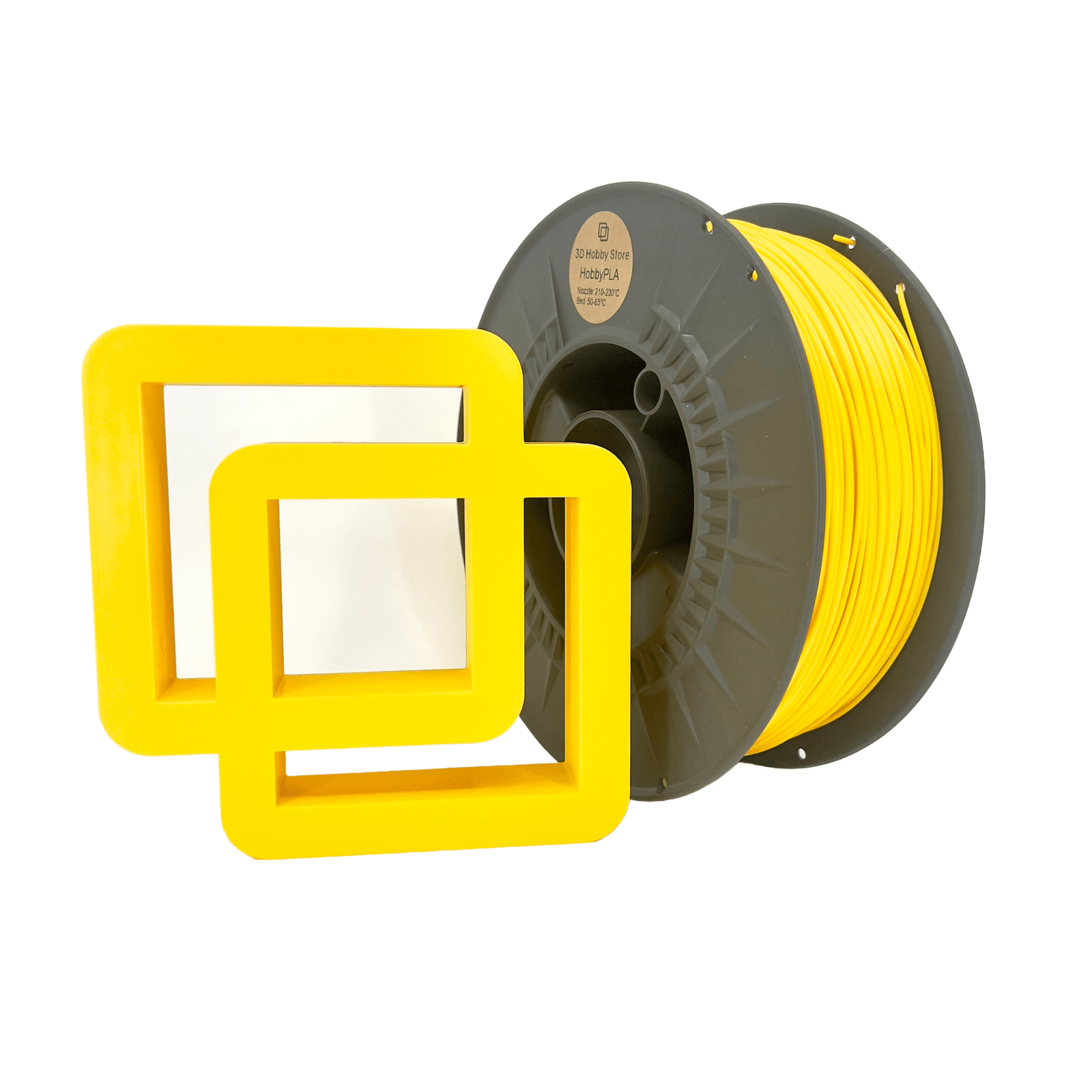

Recommended Brands & Sources

Trusted suppliers like FilaLab.shop provide premium-grade PLA filaments designed for 3D pens and printers alike. Choosing a reliable source ensures consistent quality and better results.

Preparing Your 3D Pen Setup

Choosing the Correct Nozzle & Temperature Settings

Always match your pen’s nozzle size to your filament. A 0.6–0.8 mm nozzle is ideal for most PLA filaments. Set the temperature between 180°C and 200°C for smooth extrusion. Higher temperatures can cause oozing, while lower ones may lead to under-extrusion.

Calibration & Preheating Best Practices

Allow your 3D pen to preheat fully before inserting filament. Manually feed a small amount to test flow consistency. This simple habit prevents clogs and ensures a steady filament stream.

Maintenance Tips (Cleaning Nozzle, Checking Drive Gears)

Residue buildup is a common issue. Clean the nozzle regularly using a cleaning rod or by extruding at a higher temperature to clear hardened bits. Periodically check that your drive gears are clean and aligned.

Techniques for Smooth & Precise Usage

Controlling Flow & Speed

For clean lines, keep your drawing speed steady and maintain even pressure. Fast movements may cause thin, inconsistent lines, while moving too slowly can lead to blobs.

Layering & Overhangs: When to Build Support

PLA cools quickly, making it perfect for vertical or freehand builds. However, for long overhangs, allow each layer to set before adding another to maintain structure stability.

Switching Colors or Filaments Mid-Project

When changing colors, extrude a few centimeters of new filament to clear the old one completely. This avoids color contamination and keeps transitions sharp.

Repairing Mistakes & Retraction Techniques

If you spot small imperfections, reheat and gently smooth them with the pen tip. Retraction settings (if your pen supports them) can help minimize stringing between sections.

Tips for Kids & Beginners

Choosing Safe Temperatures and Settings

Children should use PLA at lower temperatures (around 180°C) and avoid touching the hot nozzle. Always supervise to prevent accidents.

Following Simple Projects First

Beginners can start with stencils, outlines, or flat objects before moving on to complex 3D models. Gradual progress helps build control and confidence.

Supervision, Safety Gear & Workspace Setup

Set up a well-lit workspace with a heat-resistant mat. Use finger protectors if available, and keep water nearby to cool any accidental burns.

Expert Tips for Artists & Professionals

Advanced Effects: Blending, Gradients, Texturing

Mix colors by blending filaments directly in the nozzle to create gradient effects. Use rapid extrusion for textured finishes like woodgrain or stone.

Combining PLA with Other Materials

Combine PLA with resin, metal rods, or even LED lights for complex mixed-media creations. PLA’s quick-cooling nature allows stable integration with rigid materials.

Creating Professional Results & Finishing

To refine your model, gently sand surfaces or coat them with a thin layer of clear resin for shine. Professionals often polish their pieces to achieve a premium look.

Common Problems & Troubleshooting

Stringing, Oozing, or Blob Formation

This happens when temperature is too high or retraction is off. Lower the temperature slightly and use shorter pauses during drawing.

Under-Extrusion or Filament Jams

Check for dirt or moisture in your filament. A quick drying cycle or cleaning rod can often solve the issue.

Poor Adhesion or Delamination

Ensure layers are applied evenly and your pen’s temperature is consistent. Holding the pen slightly closer to the base surface can also help.

Warping, Cracking & Cooling Issues

Warping is rare with PLA, but if it occurs, ensure the room isn’t too cold or drafty, which can cool layers too quickly.

Maintenance & Long-Term Care

Storage Tips to Prevent Moisture Absorption

Store PLA in sealed bags with silica gel packets. Moisture causes bubbling during extrusion, which affects surface quality.

Routine Cleaning & Nozzle Care

Regular cleaning prevents residue buildup that can disrupt flow. If your pen isn’t used often, run filament through once a week to keep it clear.

When to Replace Parts

Replace the nozzle or feeder gears if extrusion feels rough or inconsistent. Regular maintenance ensures smooth long-term use.

Project Inspiration & Practical Applications

Kids’ Projects: Figurines, Mini Models, Playthings

Encourage children to draw their favorite cartoon characters or create custom jewelry pieces. It’s a great blend of art and STEM learning.

Artistic / Decorative Uses: Sculptures, Jewelry, Custom Embellishments

Artists can design complex mini sculptures or ornaments that showcase detail and color blending.

Professional & Prototyping Uses: Architectural Models, Functional Parts

Engineers and designers can use PLA with 3D pens to sketch prototypes or visualize product concepts quickly and tangibly.

Conclusion

Mastering PLA filament in 3D pens opens endless creative potential. Whether you’re guiding a child through their first project or refining your professional design techniques, understanding the right temperatures, materials, and care will help you achieve precise, durable, and inspiring results. Keep experimenting, stay safe, and let your imagination flow—one filament line at a time.