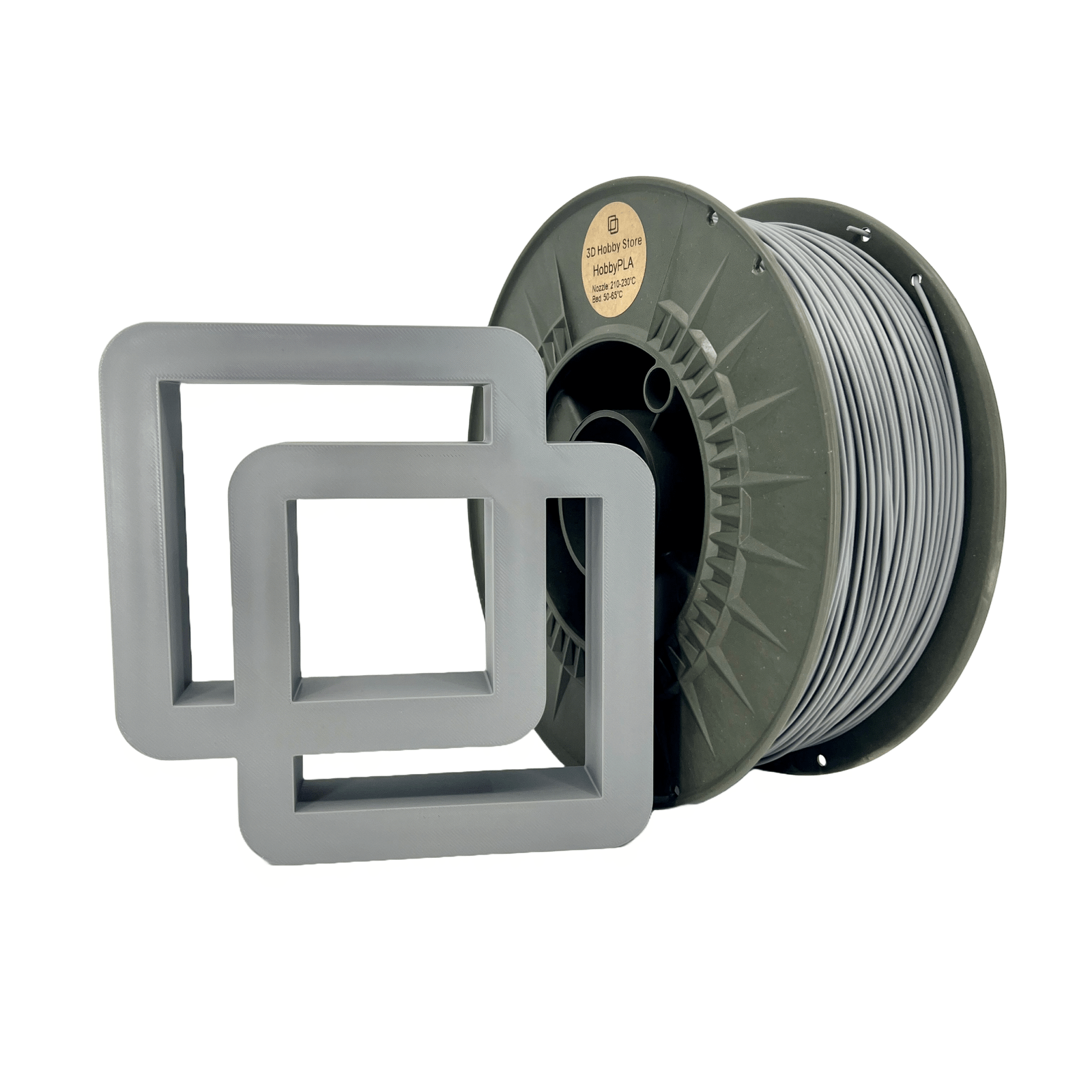

Understanding the Basics of PLA and Carbon Fiber Filament

Before diving into PLA vs carbon fiber, it’s important to understand what makes each material unique. PLA, or Polylactic Acid, is one of the most popular and beginner-friendly filaments in 3D printing. It’s derived from renewable resources like corn starch and sugarcane, making it both eco-friendly and easy to work with. Its low printing temperature and minimal warping make PLA ideal for prototypes, decorative pieces, and general-purpose prints.

On the other hand, carbon fiber vs PLA introduces a completely different category of performance. Carbon fiber filament isn’t pure carbon fiber—it’s typically a composite made by blending small carbon fiber strands with a base material like PLA, PETG, or Nylon. The result is a reinforced filament that’s stiffer, stronger, and more durable than standard PLA. This makes it the go-to choice for functional parts that must withstand stress, vibration, or high temperatures.

Strength and Durability: When Performance Matters

When evaluating PLA vs carbon fiber, strength becomes one of the most decisive factors. Regular PLA has decent tensile strength but lacks the flexibility and impact resistance needed for demanding mechanical applications. It can snap under pressure or deform under heat.

In contrast, carbon fiber vs PLA shines in situations where mechanical stability is essential. The carbon fibers within the filament act like tiny reinforcements, improving stiffness and dimensional accuracy. This makes carbon fiber composites ideal for components like drone frames, mechanical brackets, and automotive prototypes—any application where toughness matters more than ease of printing.

However, it’s worth noting that carbon fiber filaments are abrasive. They can wear out brass nozzles quickly, so switching to a hardened steel or ruby-tipped nozzle is crucial to maintain long-term print quality.

Printability and Ease of Use

When it comes to PLA vs carbon fiber, PLA clearly wins the usability battle. It prints smoothly on nearly any FDM printer, with no special hardware required. A standard brass nozzle and a basic heated bed (or even none) are enough to achieve reliable results. Its forgiving nature makes it the first choice for beginners and hobbyists who want consistency and a beautiful surface finish.

Carbon fiber vs PLA, however, demands more preparation. Because of the carbon reinforcement, these filaments can be more brittle and less flexible during extrusion. They also require higher nozzle temperatures—often between 210°C and 260°C depending on the base polymer. Moreover, achieving optimal adhesion may require an enclosure or special adhesives to avoid layer separation.

Despite these challenges, many experienced makers consider the extra effort worthwhile. Once properly tuned, carbon fiber filaments produce prints with a matte, professional finish and minimal warping—something pure PLA can’t always match.

Weight, Texture, and Dimensional Stability

Another dimension in the PLA vs carbon fiber debate is the material’s physical characteristics. Carbon fiber filaments are surprisingly lightweight relative to their strength, which is why they are often used in aerospace, robotics, and automotive industries. The inclusion of carbon fibers reduces the filament’s density while improving rigidity, resulting in parts that feel premium yet weigh less.

In carbon fiber vs PLA, PLA’s main strength lies in smooth texture and gloss. PLA prints tend to have a shiny, aesthetically pleasing surface that makes them great for display pieces, art models, or product prototypes. Carbon fiber prints, by contrast, have a matte, slightly rough surface that exudes a technical and professional look—ideal for mechanical or engineering applications.

Additionally, carbon fiber composites excel at maintaining dimensional stability. They resist warping and shrinking much better than standard PLA, particularly under varying environmental conditions.

When to Choose PLA vs Carbon Fiber

Choosing between PLA vs carbon fiber ultimately depends on your project’s priorities. If your main focus is ease of printing, affordability, and aesthetic finish, PLA remains unbeatable. It’s perfect for quick prototyping, educational use, and decorative models where performance requirements are minimal.

However, when performance, stiffness, and endurance come into play, carbon fiber vs PLA tips the scale in favor of carbon fiber composites. They’re ideal for professional engineering parts, fixtures, and load-bearing components where failure is not an option.

Another deciding factor is printer capability. If your printer supports hardened nozzles and can reach higher temperatures, upgrading to carbon fiber filament can dramatically enhance your output quality. Otherwise, PLA offers a safer and more accessible option.

Environmental and Cost Considerations

The PLA vs carbon fiber comparison isn’t just technical—it’s also practical and environmental. PLA’s eco-friendly nature makes it biodegradable under industrial composting conditions, aligning well with sustainable production goals. It’s also much cheaper, making it a cost-effective choice for large-volume projects or classrooms.

Meanwhile, carbon fiber vs PLA introduces cost and complexity. Carbon fiber filaments are generally more expensive due to the reinforcement process, and they can require additional maintenance for your printer. However, their longevity and strength often offset the initial investment, especially in industrial or functional applications.

Final Verdict: Finding the Right Balance

In the end, the PLA vs carbon fiber debate isn’t about one being strictly better than the other—it’s about context. PLA offers unmatched simplicity and a glossy finish suitable for beginners, designers, and makers focused on visual appeal. Carbon fiber composites, on the other hand, deliver professional-grade strength, reduced weight, and higher dimensional accuracy for advanced users and technical fields.

When deciding between carbon fiber vs PLA, ask yourself: do you value ease and appearance, or are you chasing performance and durability? Once you answer that, the perfect filament choice becomes crystal clear.