What is PETG?

Understanding the Material

PETG, or Polyethylene Terephthalate Glycol, is a thermoplastic polyester known for its clarity, strength, and ease of processing. It is widely used in both industrial manufacturing and consumer applications due to its excellent balance of durability and visual appeal. This versatile plastic is particularly popular in the 3D printing industry, packaging sector, and display manufacturing.

Common Uses of PETG

Beyond industrial applications, PETG has made its mark in food-related contexts. It is often used for creating clear food display cases, beverage containers, protective packaging, and even kitchenware. Its impact resistance and resistance to moisture make it suitable for environments where both safety and hygiene matter.

Is PETG Food Safe?

Regulatory Compliance

If you are wondering is PETG food safe, the answer depends on the grade and manufacturer. Many PETG materials are approved for food contact under regulations from the U.S. Food and Drug Administration (FDA) and the European Union. However, not all PETG products are created equal. Some colored or specially coated variants may not meet food-contact standards, so it’s important to verify compliance before use. Always check for certifications or documentation that clearly label the material as food-safe PETG.

Industry Applications

In the food service industry, PETG is used in refrigerated display counters, bakery cases, salad bars, and protective covers. It is valued for its ability to maintain clarity and withstand regular cleaning without clouding or degrading. This makes it a trusted choice for restaurants, grocery stores, and food packaging companies.

Why PETG is Preferred for Food Contact

Safety and Hygiene

One of the biggest advantages of food-safe PETG is that it is BPA-free and styrene-free, eliminating certain health concerns associated with other plastics. Its non-porous surface helps prevent bacteria buildup, making it easier to maintain hygienic conditions. This is crucial for environments where food is displayed or packaged for long periods.

Functional Benefits

PETG offers excellent impact resistance, ensuring that food containers or display shields remain intact even in high-traffic areas. It also has good chemical resistance, meaning it won’t easily be damaged by common cleaning agents. Its thermal stability allows it to handle moderate heat without losing its shape, although it is not suitable for high-temperature applications like ovenware.

2025 Update: What’s New in PETG Safety

Evolving Standards and Certifications

Regulatory bodies continue to update guidelines to ensure consumer safety. In 2025, there has been a stronger emphasis on traceability of raw materials in plastics used for food contact. Manufacturers of food-safe PETG now often provide full documentation on the origin and composition of the polymer, ensuring compliance with stricter standards.

Recent Developments

Some manufacturers have introduced enhanced PETG formulations designed to improve resistance to staining and odor absorption, both of which are important for reusable food containers. There is also a push toward sustainable PETG made from partially recycled materials while still meeting food safety requirements.

Choosing the Right PETG for Food Use

Material Specifications to Check

When selecting PETG for food contact, the first question should be: is PETG food safe from this specific supplier? Look for FDA or EU compliance labels, and check whether the material has been tested for direct food contact. Transparent grades are generally more likely to meet safety standards than heavily pigmented ones, but always verify.

Tips for Safe Fabrication and Use

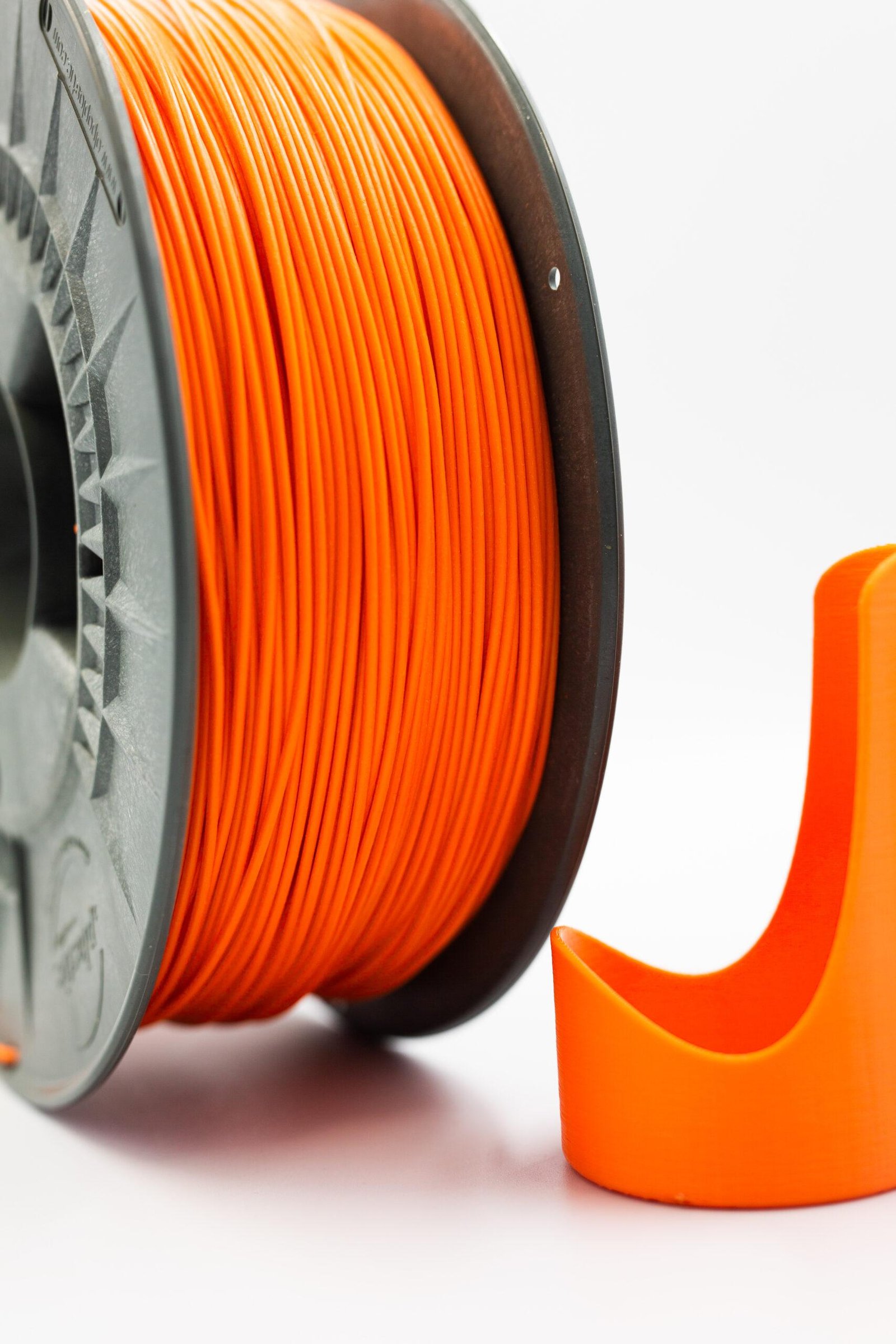

Even with certified food-safe PETG, how you cut, form, or print the material matters. Improper processing could introduce contaminants. Always use clean tools, avoid toxic adhesives, and wash the finished product before use. For 3D printing, choose PETG filament specifically labeled as food-safe and use a stainless steel nozzle to avoid metal contamination.

PETG vs. Other Food-Safe Plastics

Comparison with Acrylic and Polycarbonate

When compared to acrylic, PETG is less prone to cracking and easier to fabricate without heat-induced stress. Against polycarbonate, it offers similar clarity without the potential BPA concerns. While polycarbonate may handle higher temperatures, PETG remains a safer and more versatile choice for many food-contact applications.

When Not to Use PETG

Food-safe PETG should not be used in environments where it will be exposed to boiling water, ovens, or dishwashers that exceed its heat tolerance. Prolonged exposure to high heat can warp the material and compromise safety. It is also not ideal for acidic or oily foods that are stored long-term at elevated temperatures.

FAQs: PETG and Food Safety in 2025

- Is all PETG food-safe? No, only specific grades labeled and certified as food-safe PETG meet safety standards.

- Are colored PETG variants safe? Some are, but you must verify certifications for the exact product.

- Can PETG handle hot food or sterilization? PETG can handle moderate heat but is not suitable for boiling or high-temperature sterilization.

Conclusion & Final Recommendations

Key Takeaways

For those asking is PETG food safe, the answer is yes—provided you choose the right grade and follow safe handling practices. Food-safe PETG offers clarity, strength, and hygiene benefits that make it an excellent choice for food packaging, display, and storage.

What to Watch in 2025

With evolving standards and innovative formulations, PETG continues to be a top contender among food-safe plastics. Businesses and consumers should stay informed on regulatory updates and always ensure their PETG products meet current certifications. Choosing the right material not only ensures compliance but also protects health and enhances product longevity.