Introduction

You’ve set up your printer, loaded the filament, and waited hours—only to find another brittle, warped, or stringy mess. Sound familiar? Many 3D printing issues trace back not to the printer itself, but to widespread filament myths that mislead even experienced makers. These misconceptions waste time, materials, and energy, often pushing hobbyists and professionals into unnecessary expenses. Today, we’re debunking the most common myths about 3D printer filament to help you print smarter, save money, and get flawless results every time.

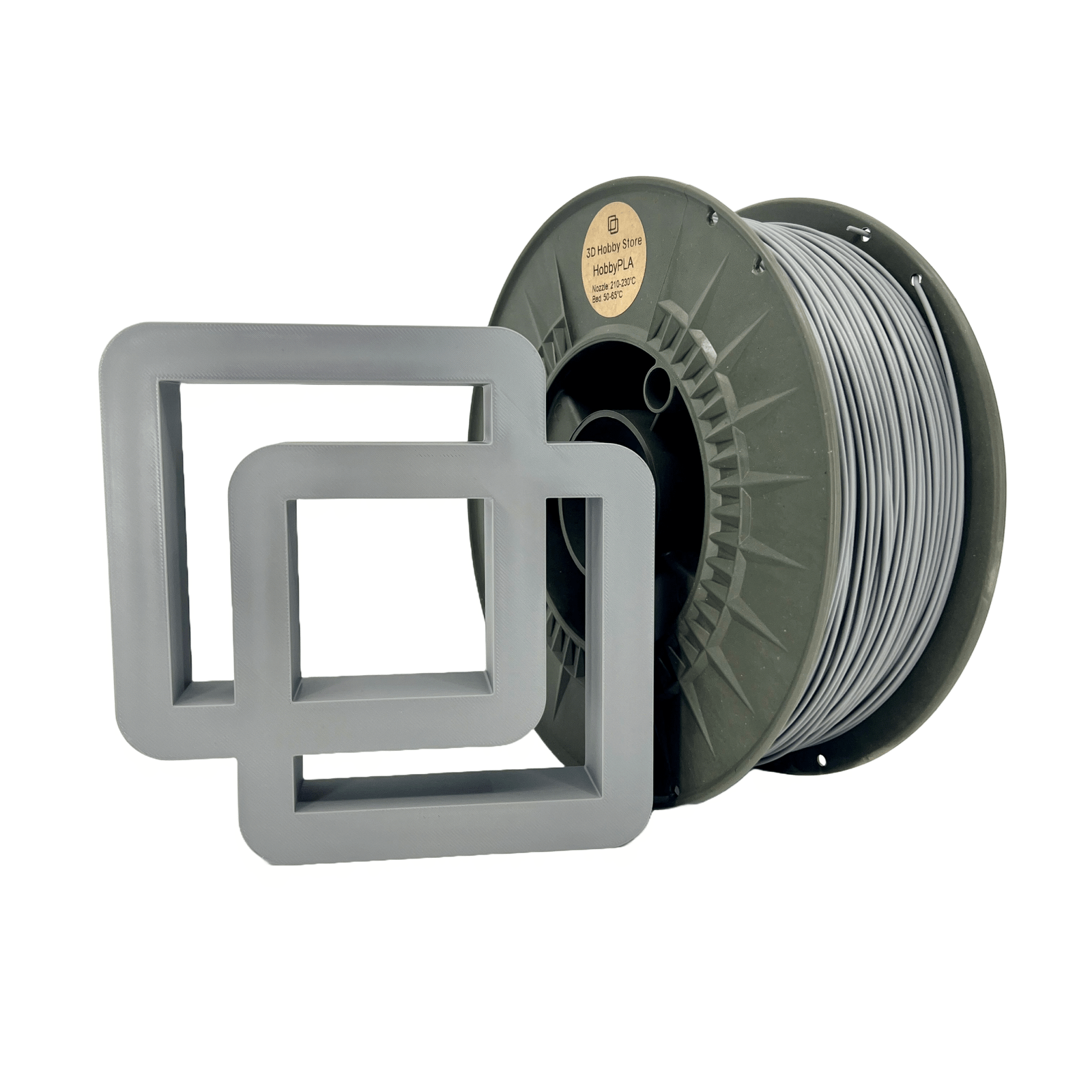

Common Myths About 3D Printer Filament

Myth 1 – “All PLA is the same quality”

It’s easy to think all PLA spools are identical, but nothing could be further from the truth. Different manufacturers use varying grades of resin, colorants, and additives that affect strength, flexibility, and print consistency. Inexpensive PLA may contain impure materials that cause uneven extrusion or clogging. Always check for details like diameter tolerance, roundness, and moisture content—these factors define true quality far more than brand labels.

Myth 2 – “More expensive filament = better results always”

A high price tag doesn’t always equal higher performance. Some mid-range filaments outperform expensive brands simply because they maintain tighter production controls. The best way to know what works? Test small before you buy big. Print calibration cubes, temperature towers, and other small test objects to verify consistency before committing to large prints.

Myth 3 – “You don’t need to control humidity”

Humidity is the silent killer of good prints. When filament absorbs moisture, it expands microscopically, leading to popping sounds, poor layer adhesion, and rough textures. PLA, PETG, and Nylon are particularly vulnerable. Filament moisture control is key: always store your spools in airtight containers with desiccants or use filament dryers before printing. Neglecting this step is one of the biggest hidden causes of failed prints.

Myth 4 – “Only brand-name filament works well”

Brand reputation can guide you, but it shouldn’t limit you. Many lesser-known or white-label manufacturers use the same raw materials as big names. Instead of relying solely on branding, evaluate data sheets, user reviews, and real-world test results. Often, you’ll discover that a smaller company offers the same—or even better—results for less.

Myth 5 – “One temperature fits all for a material type”

Every spool of filament behaves differently, even within the same material type. A standard 200°C setting for PLA might work perfectly for one brand but cause under-extrusion for another. Environmental conditions, printer hardware, and filament additives all change the equation. Always perform temperature tuning for each new spool to find the sweet spot for extrusion and bed adhesion.

How These Myths Cost You Time, Money, and Quality

Wasted material & failed prints

Ignoring proper filament handling leads to waste. A failed 10-hour print due to moisture or temperature issues can burn through hundreds of grams of material. Over time, that adds up—both in costs and lost productivity.

Increased maintenance & wear

Bad filament often leaves residue or clogs your nozzle. Each cleaning cycle shortens your printer’s lifespan and increases downtime. By focusing on filament quality rather than brand hype, you can reduce unnecessary maintenance.

Opportunity cost & lost productivity

Every failed print means more troubleshooting and less creation. Whether you’re a hobbyist or a business owner, downtime costs you—time that could be spent designing, testing, or selling finished parts.

Hidden costs of buying “cheap but bad” filament

Cheap filament can be more expensive in the long run. Replacing failed parts, wasted spools, or broken nozzles adds up quickly. Investing in quality, tested filament saves you money and frustration over time.

How to Avoid These Pitfalls — Best Practices & Tips

Choose filament based on specs, not hype

Always read the datasheet. Look for information on diameter tolerance (±0.02mm or better), roundness, and material certification. Filaments that meet ISO or ASTM standards generally offer more reliable performance.

Test small before big

Never commit a full spool to a project without a quick test print. Simple calibration cubes or layer adhesion tests can reveal inconsistencies that aren’t obvious at first glance.

Store filament properly

Filament storage matters as much as printer settings. Use sealed containers, desiccant packs, or dry boxes. For long-term storage, label each spool with the date and type, and keep them away from direct sunlight.

Fine-tune printing parameters per spool

Every new spool deserves a test run. Adjust extrusion temperature, fan speed, and retraction settings to minimize stringing and improve layer bonding. It’s an extra step that saves hours later.

Use quality control methods

Measure filament diameter periodically with calipers and inspect the surface for inconsistencies. If a spool feels rough, brittle, or emits popping noises, it’s likely absorbed moisture or degraded with age.

Filament Buying Guide: What To Look For & What to Avoid

Essential specs and features

A good filament should list:

- Diameter tolerance (tight control = smoother extrusion)

- Roundness and uniformity

- Moisture control during packaging

- Batch consistency (important for large prints)

Trusted filament brands vs emerging ones

Experiment with both. Trusted brands ensure consistency, while new manufacturers sometimes innovate with eco-friendly or specialized blends. The key is to validate performance through small tests.

Price vs value balance

Sometimes, mid-range filaments strike the best balance between quality and cost. Don’t assume “budget” means bad—what matters most is stability, printability, and consistency.

Where to buy (retailers, online, local)

Always buy from reputable sellers who store filaments properly. Counterfeit or mishandled stock—even from top brands—can cause major printing issues.

Sample Comparisons & Real-World Tests

Test Case A: print quality vs cost

Two PLA spools—one premium, one budget—can produce near-identical results when both are stored dry and printed with optimal settings. The difference lies not in cost but in consistency.

Test Case B: moisture sensitivity

A dried PETG spool prints with glossy, strong layers. The same spool left in a humid room produces cloudy, brittle prints with weak adhesion.

Test Case C: brand vs generic

Generic ABS from a trusted manufacturer matched a top brand’s performance in strength and surface finish during a head-to-head print test, proving brand loyalty isn’t always necessary.

Summary & Takeaways

The truth is simple: most 3D printing problems start with misunderstood materials. By challenging popular filament myths and focusing on real performance factors like storage, specs, and testing, you can save money and drastically improve print quality. Every successful print starts with knowledge—and now you’ve got it.