3D printing is redefining the way we approach everyday kitchen tools. From cookie cutters to custom storage containers and measuring spoons, makers around the world are turning to desktop 3D printers to create personalized culinary gadgets. But with this new wave of creativity comes a serious question: Are the filaments used in 3D printing actually safe for food contact? Let’s break down which materials are safe, which should be avoided, and how you can print kitchen tools with confidence and care.

Understanding What “Food-Safe” Means in 3D Printing

In the world of 3D printing, “food-safe” refers to a material’s ability to come into contact with food without leaching harmful substances, supporting bacterial growth, or degrading over time. To be officially deemed food-safe, a filament must meet regulatory standards such as FDA compliance (U.S.) or EU Regulation No. 10/2011.

However, even if a filament is labeled as food-safe, it can lose that status if printed incorrectly or exposed to contaminants like lead or copper from non-food-safe printer nozzles. Surface finish, porosity, and post-processing also play critical roles in determining overall safety.

Top Food-Safe Filaments You Can Rely On

Here are the most recommended filament types for printing kitchen tools — assuming proper printing conditions and clean, food-dedicated equipment.

PLA (Polylactic Acid)

PLA is one of the most commonly used filaments in desktop 3D printing. It’s derived from renewable resources like cornstarch and sugarcane, making it biodegradable and generally safe. However, not all PLA is food-safe by default — additives and colorants can make a difference.

Choose unpigmented or explicitly food-safe certified PLA, especially for short-term contact items like cookie cutters. Keep in mind that PLA has a low heat tolerance, so it’s not dishwasher-safe or ideal for hot food.

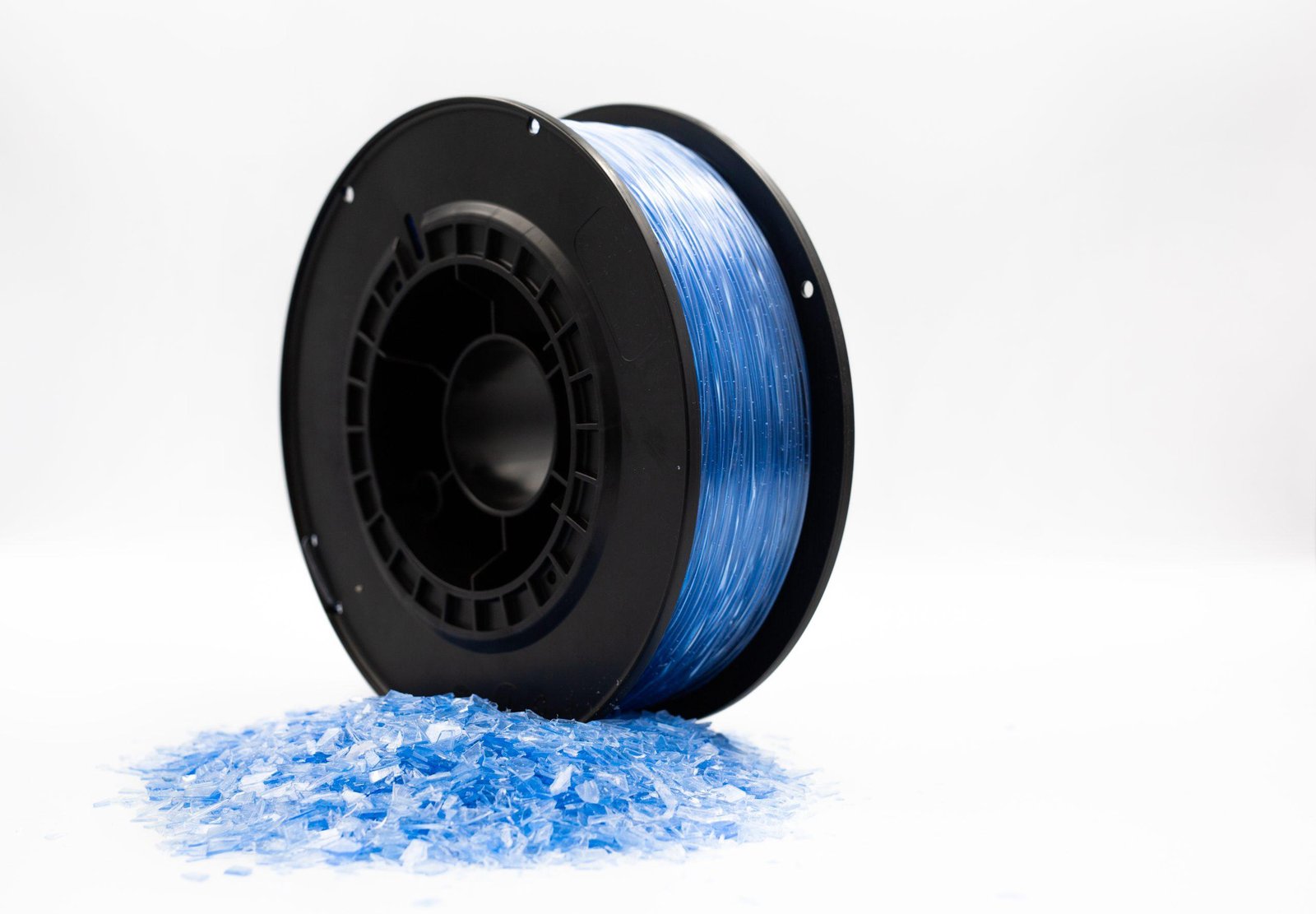

PETG (Polyethylene Terephthalate Glycol-Modified)

PETG is a favorite among kitchen tool creators due to its excellent chemical resistance, heat tolerance, and smoother surface finish, which makes it easier to clean. Many PETG filaments are FDA-compliant, and the material itself is used in water bottles and food containers globally.

For utensils and items exposed to slight heat or repeated use, PETG is one of the best choices available — especially when printed with a stainless steel nozzle and sealed properly.

Polypropylene (PP)

Polypropylene is considered a top-tier option for long-term food contact. It is used extensively in commercial food packaging because it’s chemically inert, heat-resistant, and naturally hydrophobic. However, it can be tricky to print, requiring precise settings and bed adhesion techniques.

FilaLab.shop offers specialty PP blends that simplify the printing process while maintaining safety and durability, making it a solid pick for advanced users.

Nylon (Only Certain Grades)

While industrial-grade nylon is sometimes approved for food contact, most hobby-grade nylon filaments are not food-safe by default. Nylon is prone to absorbing moisture, which can compromise cleanliness, and it often contains additives or dyes. If you use nylon, only trust explicitly certified versions and be prepared to seal the surface.

Filaments You Should Avoid for Food Contact

ABS (Acrylonitrile Butadiene Styrene)

ABS is popular for its durability, but it’s not food-safe. It releases toxic fumes during printing, often contains colorants or plasticizers, and creates rough, porous prints that can harbor bacteria. Skip it for anything kitchen-related.

TPU/TPE (Flexible Filaments)

Flexible filaments may seem appealing for printing gaskets or squeezable containers, but they’re usually unsuitable for food applications. Their soft, porous surfaces are difficult to sanitize and prone to bacterial buildup.

Printer Nozzles Matter: Avoid Contamination

Even if your filament is food-safe, your printer setup might not be. Standard brass nozzles often contain trace amounts of lead, which can leach into the print.

Always use a stainless steel or certified food-grade nozzle when printing kitchen tools. Additionally, dedicate a specific nozzle or printer to food-safe projects to avoid cross-contamination from prior prints.

Post-Processing: Seal and Sanitize

3D printed parts have layer lines that can trap bacteria. Here’s how to make your prints safer:

- Sand the surface to reduce porosity

- Apply food-safe epoxy coatings to seal the layers

- Avoid harsh chemicals that may degrade the filament

- Do not use a dishwasher unless the filament is rated for high temperatures

Proper post-processing is often the key to turning a food-safe filament into a truly food-safe final product.

FilaLab’s Food-Safe Filament Selection

At FilaLab.shop, we offer a curated selection of food-safe filaments, including certified PETG, unpigmented PLA, and print-optimized PP blends. Each filament is sourced from trusted manufacturers and rigorously tested for quality. Whether you’re creating cookie cutters, cutting boards, or spice containers, FilaLab has the right material for your next kitchen-friendly print.

Conclusion: Print Smart, Stay Safe

3D printing your own kitchen tools is both fun and functional — but safety always comes first. Stick to known food-safe materials like PETG and PP, use stainless steel nozzles, and invest time in post-processing your prints. Most importantly, source your filaments from reliable suppliers like FilaLab.shop, where food safety and filament quality are never compromised.

Start your next culinary creation with confidence — and the right filament.